-> HathiTrust Digital Library Site; Link to First Page.

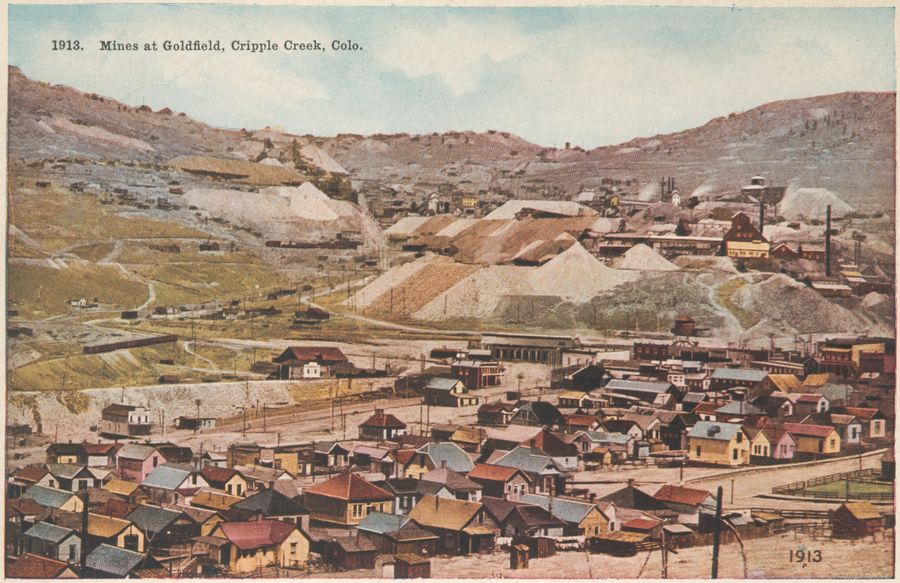

I added the Mines at Goldfield image from my collection, source only had the two drawings.

Within the past few months there has been introduced into the Cripple Creek district a new type of boiler furnace that bids fair to revolutionize the operation of steam plants throughout Colorado as well as the West and Northwest.

It is a lignite burner, and embodies the application of the gas-producer principle to boiler practice—a system that develops and effectually burns all of the volatiles or hydro carbons and at the same time completely consumes the fixed carbons. This is accomplished in such a manner as to allow no cold air to enter and cool the gases or neutralize the work already done.

The fuel is burned in a bed about two feet deep on patent water cooled rocking grates of simple design and durable construction. Steam is introduced into an air-tight ash pit with which sufficient air is allowed to enter to burn the fixed carbons in the fuel bed. The volatiles or hydrocarbons, which comprise a large per centage of the calorific value of lignite coals, are burned as they rise from the fuel bed.

This is accomplished by the introduction of heated secondary air at this point. Before entering the furnace this air travels through iron pipes placed in the combustion chamber from which it enters a hollow bridge wall and from thence passes into hollow side walls on either side of the furnace from whence it is discharged into the furnace through openings underneath a fire brick arch that partially covers the firebox.

The air is drawn through these passages solely by natural draft, and without the use of blowers or fans. After having been in contact with heated surfaces for a considerable distance the air becomes so thoroughly heated that it enters the furnace at from 300° to 700° F.

This fact insures a rapid and complete mixture with the rising gases from the burning fuel and gives practically complete combustion.

The steam and air entering the ashpit is gently forced up through the fuel bed, which is in various stages of combustion, from a live fire on top down to a dead ash, from which all combustibles have been consumed. The moisture derived from the steam in the ashpit is sufficient to rot and disintegrate what clinkers there may be, so that they readily crush between the rocking grates as they pass downwards.

Fires are never cleaned from above with this system. Everything passes downward through the rocking grates and when the ashes are finally taken from the pit it is after the carbon has been entirely consumed and the product moist and easy to handle.

The Golden Cycle Mining Company was the first concern to take advantage of this invention, and by its use under four boilers at their mines in Cripple Creek district are saving about $50 per day, or 34.2% in fuel costs. Indeed so well pleased are they with it that they have given an order to have the roasters at their new mill in Colorado Springs equipped with these furnaces, and seventeen are now being constructed at that place.

The Vindicator mine on three boilers, served with this lignite furnace and burning Colorado Springs coal, are saving $1,200 per month, while at the Granite mine, with two boilers thus served, the fuel bills have been reduced by more than $1,000 per month.

There is nothing extravagant in the claims made for this furnace. It merely develops and applies the fuel values that have heretofore gone to waste. The Colorado lignites are really almost as valuable as the Colorado bituminous coals. As a matter of fact, analysis shows them to contain about 90% of the heat units contained in the latter.

The trouble has simply been that with the methods heretofore in vogue much greater losses were experienced in burning lignite than in using bituminous.

It is not uncommon, with a good grade of bituminous coal to find plants that are able to put 60% or 65% of the B. T. U. value contained in the coal into the water, while 50% is a remarkably good record for lignite. When it is once understood that this new furnace puts from 70% to 80% into the water while using lignite it will be appreciated that it works wonders with the so-called "poor fuels."

The action of the furnace is such as to develop a soft gas flame twenty to thirty feet in length, and is much easier on a boiler than any other known system. The long flame gives an even distribution of heat and gets action on every square inch of boiler-heating surface. Boilers are never blistered with this system, and the firebox itself does not become so intensely hot as to damage the setting.

With this furnace it is an easy matter to drive a boiler to its utmost without putting it to the strain experienced with the old system in burning what is generally termed "good steam coal."

These furnaces are built by the Western Furnace Company of Denver, which company is making very liberal guarantees of their efficiency.

crpd1_tubular-boiler-setting-w-lignite-furnace.png)

crpd2_water-tube-boiler-setting-w-lignite-furnace.png)