-> HathiTrust Digital Library Site; Link to First page of article.

With which is Incorporated the "Pacific Coast Miner"

I added the 2 maps from Hills 1900 Manual + the image from my collection.

COST keeping in industrial establishments, as well as in mining work, has of late years been given considerably more attention than it had received formerly, and by detailed investigation the share of the various operations in the general cost of operation has been carefully ascertained. It is a very difficult matter to compare costs of different mines with each other because the conditions may vary considerably in each case.

There are, however, some operations which are common to all mine work, as the ore has to be broken from the ground and it has to be transported and the metal has to be extracted. Accessory costs, such as timbering and pumping, and general costs, such as supervision, sampling and surveying, should be apportioned among those headings.

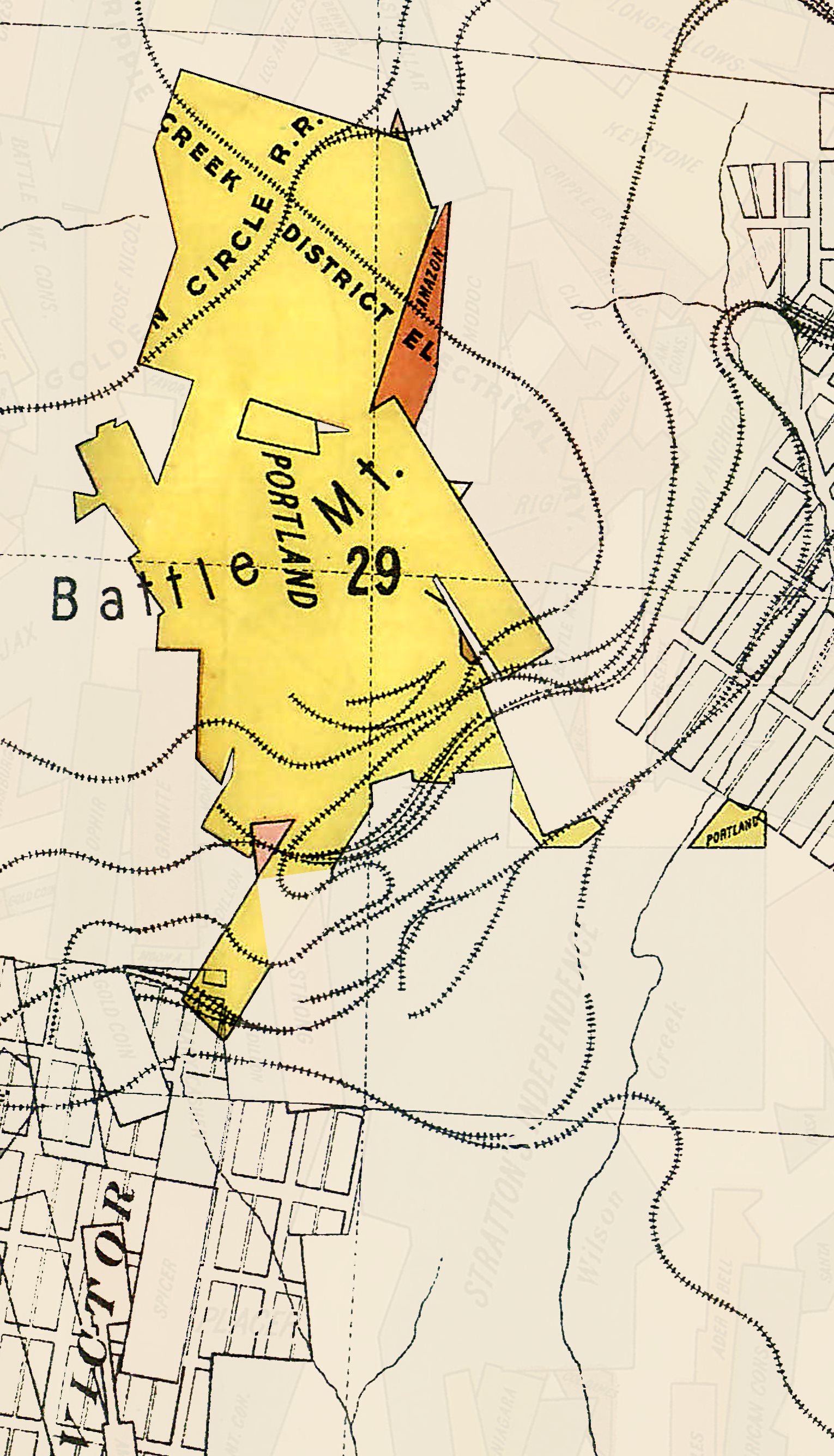

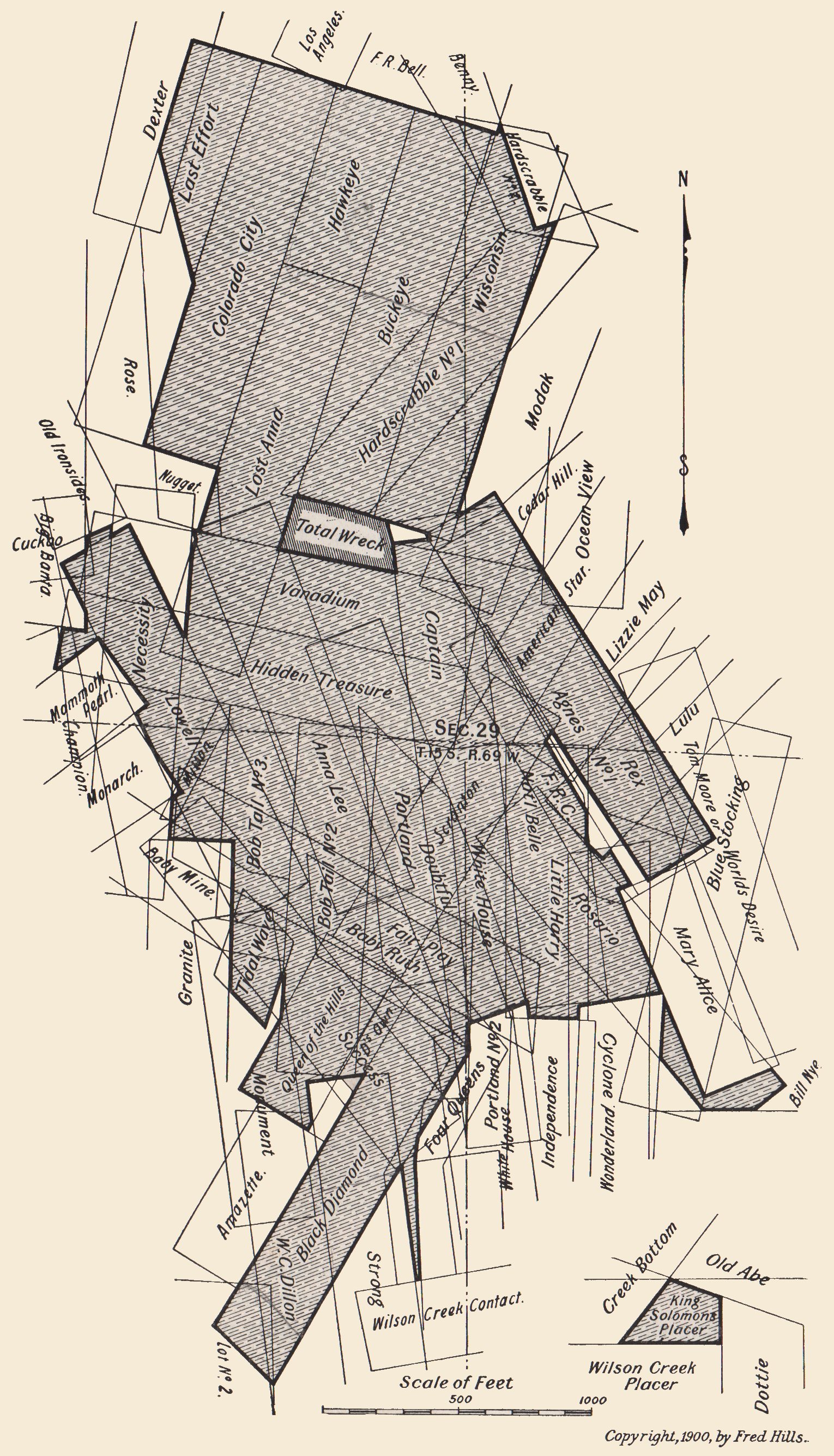

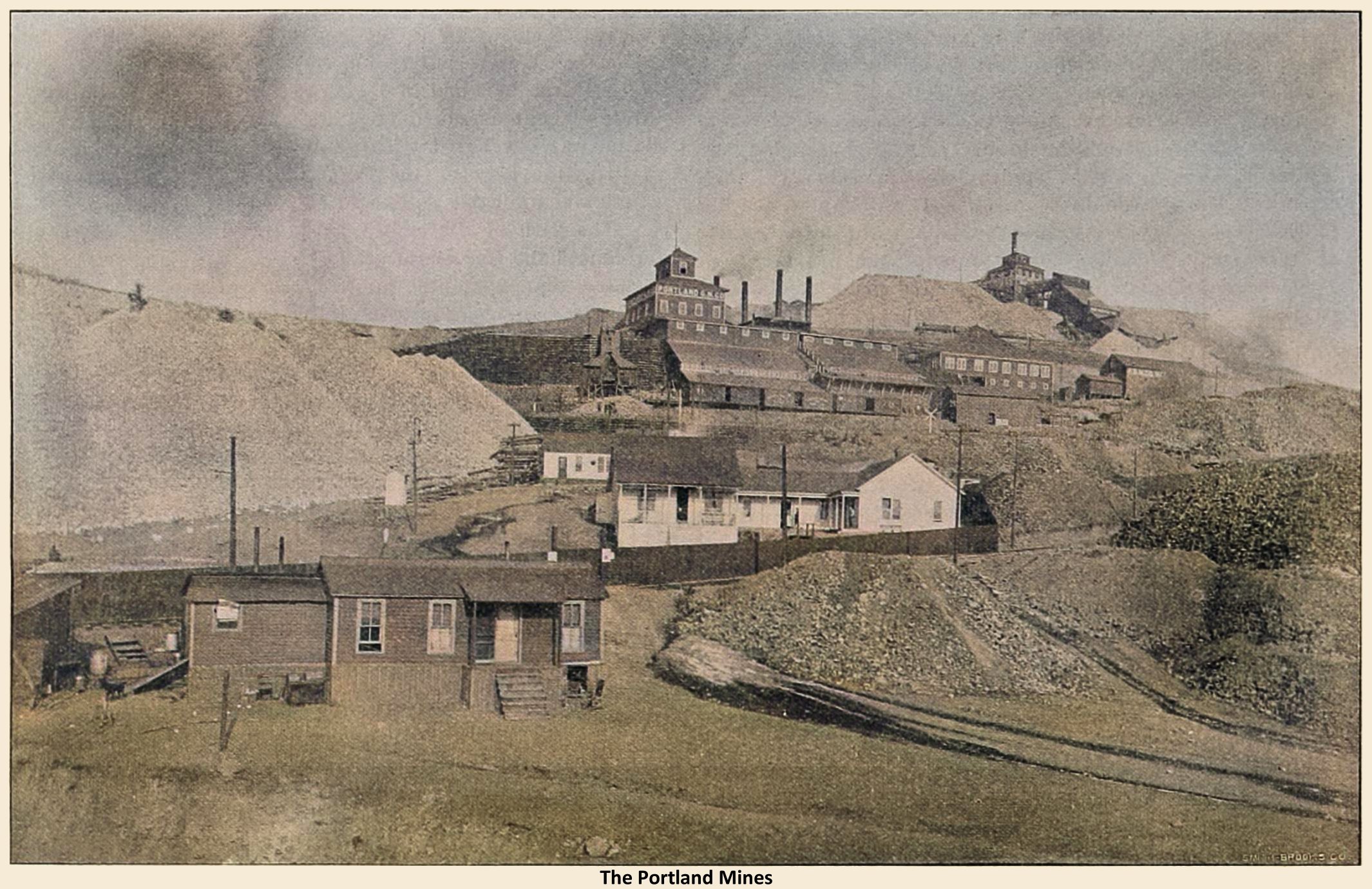

The author in the above article in the Bi-monthly Bulletin of the American Institute of Mining Engineers for November, 1905, gives an exposé of the system of cost keeping which is in use at the Portland Gold Mining Company in Cripple Creek, Col. The marketable product of the company is only gold.

The accounts are divided into four main headings, namely, milling, plant and development, stoping and distributed accounts. The latter account does not figure by itself in the operating costs, but the amounts which it includes are distributed or charged out among the other three heads, that is to say, the accounts which do not bear directly upon the mining of the ore are charged out to those accounts which do.

Thus, for example, the total cost of running the boiler room is distributed to the various purposes for which steam is used, such as hoisting or compressing. For instance, if the amount of steam is added to the hoisting account, it, together with the other debit items of the hoisting account, shows the total cost of hoisting. This, then, is charged out or credited under the head of stoping to the account of hoisting ore, and under the head of development to the accounts of drifts, cross-cuts, etc., on the basis of tonnage hoisted from stopes, drifts, cross-cuts, etc. Thus all the distributed accounts eventually find their way into the three main accounts mentioned above which bear directly upon the mining of the ore.

The milling account is comparatively simple, inasmuch as the Portland mill is not situated near the mine and the mill accounts are, therefore, kept separate. Under milling there are, therefore, only two items, namely, "total freight and treatment on ore sent to the Portland mill" and "total freight and treatment on ore shipped elsewhere."

The two items are kept separate so as to compare the cost of treatment at the company's mill with that of custom work.

The plant and development accounts include only new buildings for the installation of new machinery under the former head and underground operations of the nature of permanent equipments under the latter head. For instance, development work would include a new shaft to facilitate hoisting, a new drift to open up a vein or veins, or a cross-cut to explore virgin territory. Development is considered to embrace only those operations which could be cut off without materially affecting the production of ore.

All other costs are charged to stoping, a comprehensive account, which is considered to include all ordinary running expenses. The stoping account has a number of different sub-heads.

Under "breaking ore" is included everything from drilling into the solid rock to delivering the ore into the chutes ready for the trammers, as well as the work of the machine drill men, hand miners and muckers, machine drills, explosives, etc.

The "tramming" account includes the cost of getting the ore from the chutes to the stations of the shafts, including repairs to tracks and tram cars.

The "hoisting" account embraces the cost of raising ore and waste to the surface, delivering the ore to the bins and depositing the waste on the dump. It includes the cost of running the hoisting engines, the labor cost of the cages and skip tenders, repairs to the shaft and machinery and the surface tramming and tram tracks.

The "timbering" account includes the cost of both labor and material used in keeping the mine timbered,

and under the head of "sorting and loading" all expense of hand concentration, the cost of tramming to the dump, the waste picked from the ore, loading the ore into railroad cars for shipment, keeping the ore houses and bins in repair are accounted for.

"Pumping" includes the cost of keeping the mine dry and repairs to both pumps and lines;

"lighting," the cost of electric lights and lines and candles issued to the miners;

"assaying," the cost of mine sampling,

and "surveying," everything in the mine engineering line.

Under the head of "repairs" there are entered only those charges for general wear and tear which are not directly chargeable to any of the above heads, such as, for instance, painting the shaft house.

The general expense account includes office accounts of both the Victor and the Colorado Springs offices, salaries of directors and officials, etc. The insurance and taxes accounts include amounts paid for insurance and taxes on all mining property, and the litigation account includes all legal expense connected with the mine.

The account called "development charged to stoping" covers the cost of those pieces of exploration work which produce ore in their progress. The general cost sheet is supplemented by two auxiliary cost sheets, one for stoping and one for development.

On one or the other of these is found the cost of operation in detail, as well as the production and progress of each working place in the mine. The following table shows the method of tabulating the costs of compressing, hoisting, electric plant and machine drilling, the figures applying to the month of December, 1902:

| Compressing. | Dr. | Compressing. | Cr. | |

| Boiler room, steam | $2,561.63 | Machine Drills | $2,993.83 | |

| Machine shop, repairs on compressors and air lines | 22.54 | |||

| Supplies, oil waste, packing | 130.66 | |||

| Pay roll, engineers | 279.00 | |||

| —————— | —————— | |||

| $2,993.83 | $2,993.83 | |||

| Hoisting. | Dr. | Hoisting. | Cr. | |

| Boiler room, steam | $1,840.35 | Tons. | ||

| Machine shop, repairs on engines | 34.97 | Stopes (hoisting ore) | 17,407 | $4,118.60 |

| Blacksmith shop, repairs on engines | 16.95 | Drifts | 1,536 | 363.54 |

| Carpenter shop, repairs on engine room | 19.75 | Cross cuts | 2,439 | 577.20 |

| Supplies, lubricants, packing | 363.08 | Raises and winzes | 373 | 88.32 |

| Pay roll, hoisting engineers | 2,886.44 | Shaft No. 1 | 66 | 3.31 |

| General office | 5.00 | Shaft No. 2 | 14 | 15.57 |

| —————— | —————— | —————— | ||

| Cost of hoisting 21,835 tons | $5,166.54 | 21,835 | $5,166.54 | |

| or $0.2366 per ton. | ||||

| Electric Plant. | Dr. | Electric Plant. | Cr. | |

| Boiler room, steam for generator | $527.45 | Lighting (mine and surface) | $914.08 | |

| Machine shop, electrician and repairs | 208.85 | |||

| Supplies, lamps, wire, etc. | 177.78 | |||

| —————— | —————— | |||

| $914.08 | $914.08 | |||

| Machine Drills. | Dr. | Machine Drills. | Cr. | |

| Boiler room, steam hammer | $41.87 | Shifts. | ||

| Compressing, air for machines | 2,993.83 | Breaking ore | 1,575 | $3,648.71 |

| Machine shop, repairs on machines | 203.58 | Drifts | 267¾ | 620.42 |

| Blacksmith shop, sharpening steel | 1,728.13 | Cross cuts | 365 | 845.37 |

| Supplies, repair parts and new steel | 599.88 | Raises and winzes | 66 | 151.70 |

| Shaft No. 2 | 10 | 23.16 | ||

| Shaft No. 3 | 120 | 277.93 | ||

| —————— | —————— | —————— | ||

| Cost of operating | $5,567.29 | 2,403¾ | $5,567.29 | |

| 2,403¾ shifts, or $2.3166 per shift. | ||||

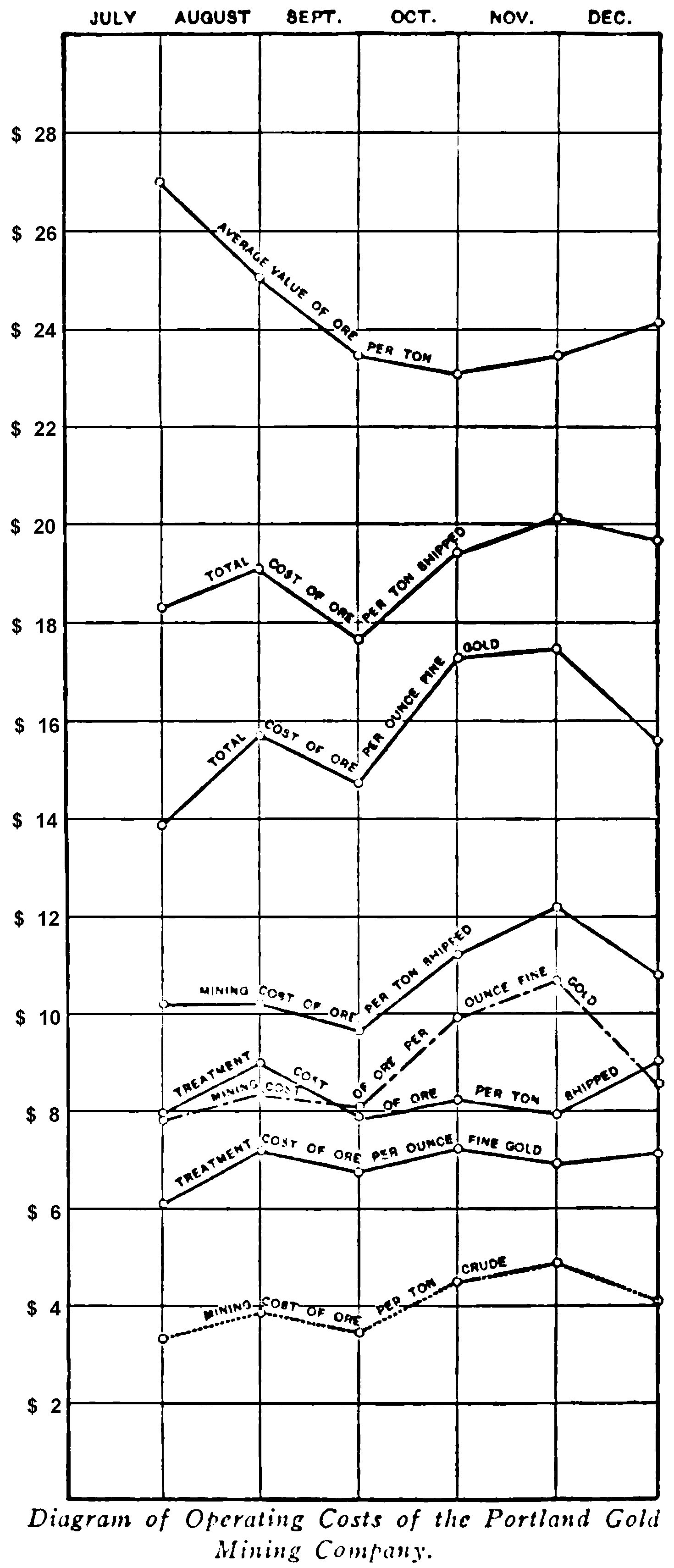

The results of the cost sheets, such as the total cost of mining and the cost of milling per ounce and per ton, and several other items of general interest are plotted into curves such as are shown in the adjoining figure.

The upper line in this diagram represents the average value of the ore in dollars per ton shipped, and the next line below shows the total cost of producing and marketing a ton of ore, the difference between it and the first line representing the net profit per ton.

The second line is the sum of the two smooth lines below, namely, the cost of mining and the cost of treatment. Similarly, the next broken line below, that is, the cost of producing an ounce of fine gold, is composed of the two costs represented in the two lower broken lines, representing the cost of mining an ounce of gold and of extracting that amount from the rock. The dotted line at the bottom represents the cost of mining a ton of crude rock.

A new form of cost sheet which has recently supplanted the old form differs from the latter in the greater amount of detail shown. There is also an account added called Invoice, which comprises such accounts as supplies, timber, explosives and fuel. These are charged out as used and debited as bought, and the credits and debits therefore do not balance on the old sheet. This difference is charged to "invoice" and shows the amount of the above supplies in stock.

The basis for the auxiliary sheets mentioned above is the shift boss' distribution sheet, one of which is used for each stope, drift, cross-cut, etc., in the mine, and upon which the shift boss enters the distribution of his shift.

The tonnage from each place is obtained by counting the number of trammers' tags from that place, multiplying them by the car constant, which is 0.7 tons. The trammers place these tags upon the cars as they leave them at the stations, and the top men remove them and turn them into the office.

The explosives and the lumber and timber are entered upon the sheets directly from the powderman's and the head timberman's reports.

The cost for machines is the debit against machine drills on the cost sheet distributed on the basis of the number of drill shifts worked.

The other costs are taken from the cost sheet and distributed on the basis of tonnage. The column for feet of progress on the development sheet is filled in by the surveyor.

The author remarks that it will doubtless be said that this system of keeping costs throws a good deal of clerical work upon the shift bosses and the foremen. He maintains, however, that there is nothing complicated in what these men are asked to do, nothing that a man with average intelligence enough to be a good foreman cannot do in twenty or thirty minutes at the close of the shift.

He believes that this expenditure of time more than pays for itself in giving the foreman a review of the work of the day and a basis for the plans of the next. By obtaining the co-operation of the foreman, this system is not nearly so expensive as may be imagined.

The author claims that the excellent showing made by the Portland mine in recent times is entirely due to close supervision guided by the cost sheet.