-> HathiTrust Digital Library Site; Link to First Page.

I reused a image from my collection as source had none

The subject of cyaniding is intensely interesting. Since the third annual meeting of the association at Deadwood, S. D., Jan. 2-4, is to be a "Cyanide Meeting," I regret very much not to be able to attend.

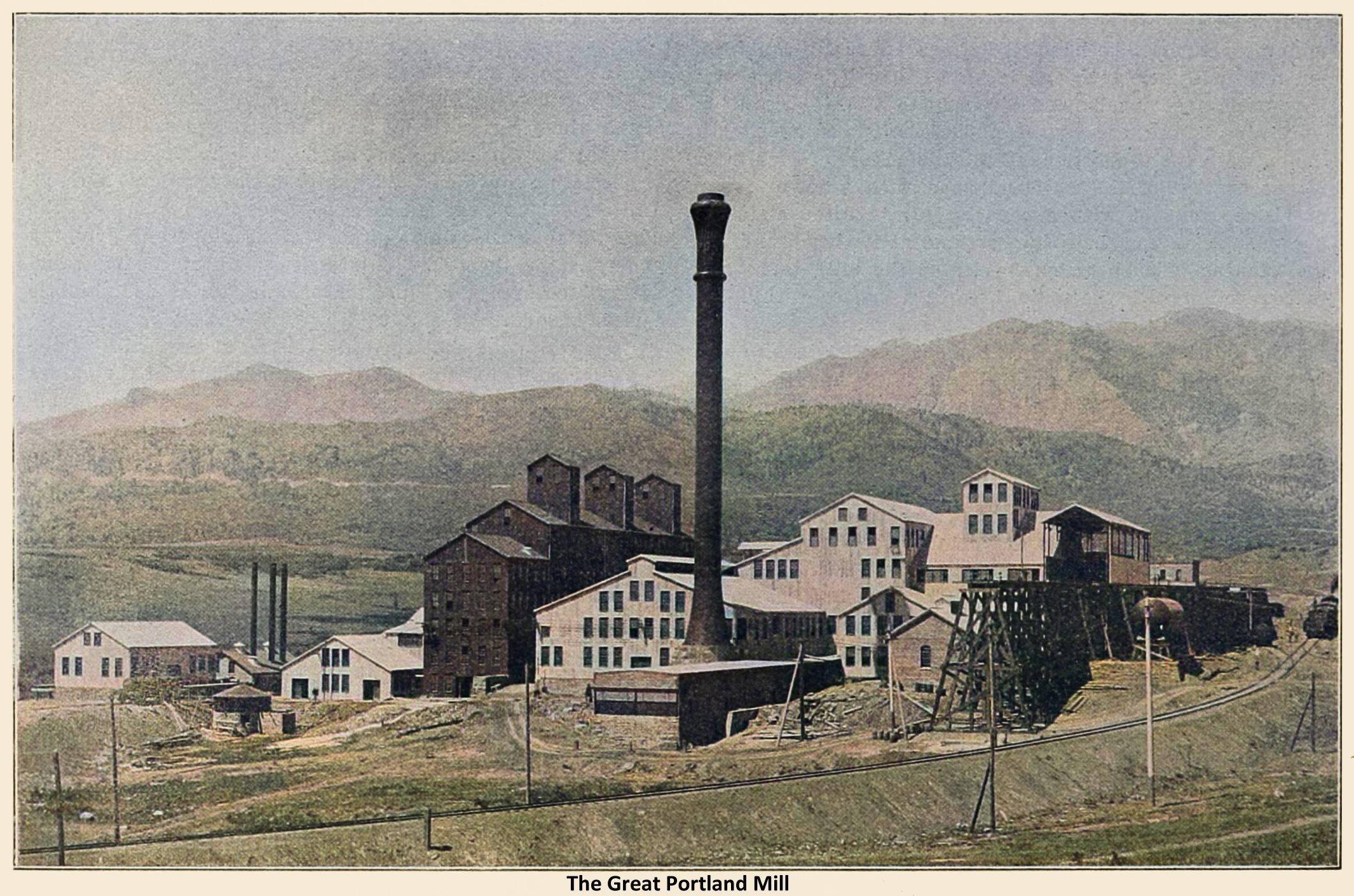

We of the Portland mill are always ready to learn, and as gladly give to those interested all which our experience may have taught us—methods, costs and results.

An article in Mining Reporter, Oct. 24-31, about the Portland company's cyanide mill, by Regis Chauvenet, gives a very complete account of the mill. I shall try to say something about our precipitation and clean-up.

The precipitation room is large and well lighted and contains 18 rows of zinc boxes, each row having 6 compartments 4 ft. x 4 ft. x 4 ft. and pyramidal in shape at the bottom.

A 14-mesh wire screen supported by 2-in. angle iron rivited on the inside 20 inches above the lowest point of the pyramid forms the false bottom.

The solution enters the first box through a false compartment, flows under the screen, then up through the zinc and over into the next compartment; the distance from the screen to the overflow of each compartment is 28 in. These boxes are supported on timbers high enough above the floor below (which is of cement) to permit a man to stand up to work about them.

Beneath each row of boxes there is a 12-in. x 12-in. wooden launder, which carries the discharge to a launder of the same dimensions, which discharges into a steel tank with capacity for holding all of the solution from one row of zinc boxes during a clean-up.

This tank is connected to a 2-in. centrifugal pump, which lifts the contents 30 ft. to 3 lead-lined tank (8 ft. in diam. and 10 ft. high). Over this tank there is built a hood having a 12-in. x 12-in. opening in the center for the escaping fumes during a clean-up.

These gases are assisted out of the hood by means of an air jet. Air is also used to agitate the mixture in the tank when cutting down the zinc.

Of the 18 sets of zinc boxes we are using 12, each compartment of which is packed with 200 lbs. of zinc shavings previously dipped in a 2% acetate of lead solution. The total amount of zinc used to pack the boxes is 14,400 lbs.

Strong solution flows through six rows of boxes - the strength of cyanide per ton of solution being 0.6 lb., and the protective alkalinity 0.5 to 1.0 lbs.

Weak solution flows through the other six boxes—the strength of cyanide per ton of solution being 0.3 to 0.4 lb. and the protective alkalinity, neutral to 0.2 lb.

On the strong side, from 500 tons to 600 tons of solution flows through in 24 hrs., while on the weak side from 800 tons to 1,000 tons - a total of from 1,300 tons to 1,600 tons daily. The gold contents in the solution entering the strong side varies from 20 cts. to 40 cts. per ton, while the weak solution contains from 10 cts. to 20 cts.

Our precipitation is remarkably good - showing only a trace in gold and 4 cts. being high.

A white precipitate forms on all the boxes at the head compartment, this condition being more pronounced on the weak side - in fact, so great is the amount formed on this side that it necessitates a separation of this muck from the fine zinc when we clean up.

It readily falls off when the zinc is disturbed. It consists of calcium ferro-cyanide, zinc hydrate, calcium sulphate, calcium carbonate and fine slime from the sand filters.

The formation of this white precipitate in such large quantities on the weak side is a rather curious fact, when it is remembered that the strong side carries the strongest percentage in lime. The only explanation I can give for it is that the solution is so weak in both cyanide and protective alkalies that it has not suficient strength to hold it in solution when in contact with the zinc.

To show just what this separation of muck, or white precipitate and fines or slime means, I will give some figures. The first few times we cleaned up, everything was acid treated, and sent to the melter.

The total dry weight was 1,200 lbs., which took several days to melt and yielded a very small button as a result. By making this separation the melter gets from 100 lbs. to 150 lbs., which, when melted, gives very respectable buttons, the remaining 1,000 or 1,100 lbs. not being worth melting, and being a good product for the smelter.

We have no separation of this kind to make on the strong side; everything goes into the acid treatment tanks, is then filter-pressed and sent to the melter. The value of the slimes per lb. after roasting is from 1 oz. to 3 ozs. gold, and the same in weight of silver; in other words, the gold and silver are of about equal weights, the former being perhaps slightly in excess.

* Abstract from Western Chemist and Metallurgist. January 1908.