-> HathiTrust Digital Library Site; Link to First page of article.

Source had 1 image, and I added one extra image from my collection.

Among the leading gold-producing districts of the world the Cripple Creek district of Colorado stands as one of the foremost. This volcanic area, three miles long by five miles wide, embodies a network of gold-carrying veins running in all directions, intersecting each other and comprising a series of shoots, the magnitude of which is inconceivable.

These ore bodies have in the past produced, and are now producing a large tonnage of ore of exceptional richness. Along with the development and mining of these higher grades of ore material has simultaneously been developed which, although of sufficient value to term ore did it exist in some other districts of the world, is, on account of its refractory nature, left standing in the mine slope or thrown upon the waste dump.

The refractory nature of these ores is due largely to the occurrence of the gold in combination with tellurium, forming a compound (AuAg)Te2, which is represented by the minerals calaverite, or sylvanite, and also to the association or encasement of these gold tellurides in crystal growths of the characteristic mineral pyrite.

The history of the metallurgical treatment of these ores is of great interest, and is conspicuous for the number of metallurgical failures which have taken place, due largely to the difference in the physical properties existing between gold and telluride and native gold, and partly to the insolubility of the tellurides in cyanid solutions.

Stamp milling followed by amalgamation was first tried; concentration failed, whilst at the smelting works these ores were not desirable owing to the high siliceous character. Only after roasting to free the gold of its volatile associate have the ores been susceptible to lixiviation processes.

Consequently, roasting followed by barrel chlorination and concentration has become the popular treatment. This method works very well so far as the extraction is concerned, and will continue to be used so long as the present grade of ore is maintained; but as the amount of low-grade ore standing in the stopes and upon the dumps becomes larger year after year, it becomes more apparent that a cheaper method of treatment must be found, the problem resolving itself into one of raw treatment at the mine, rather than transporting 50 miles by rail to the cheap fuel in the valley.

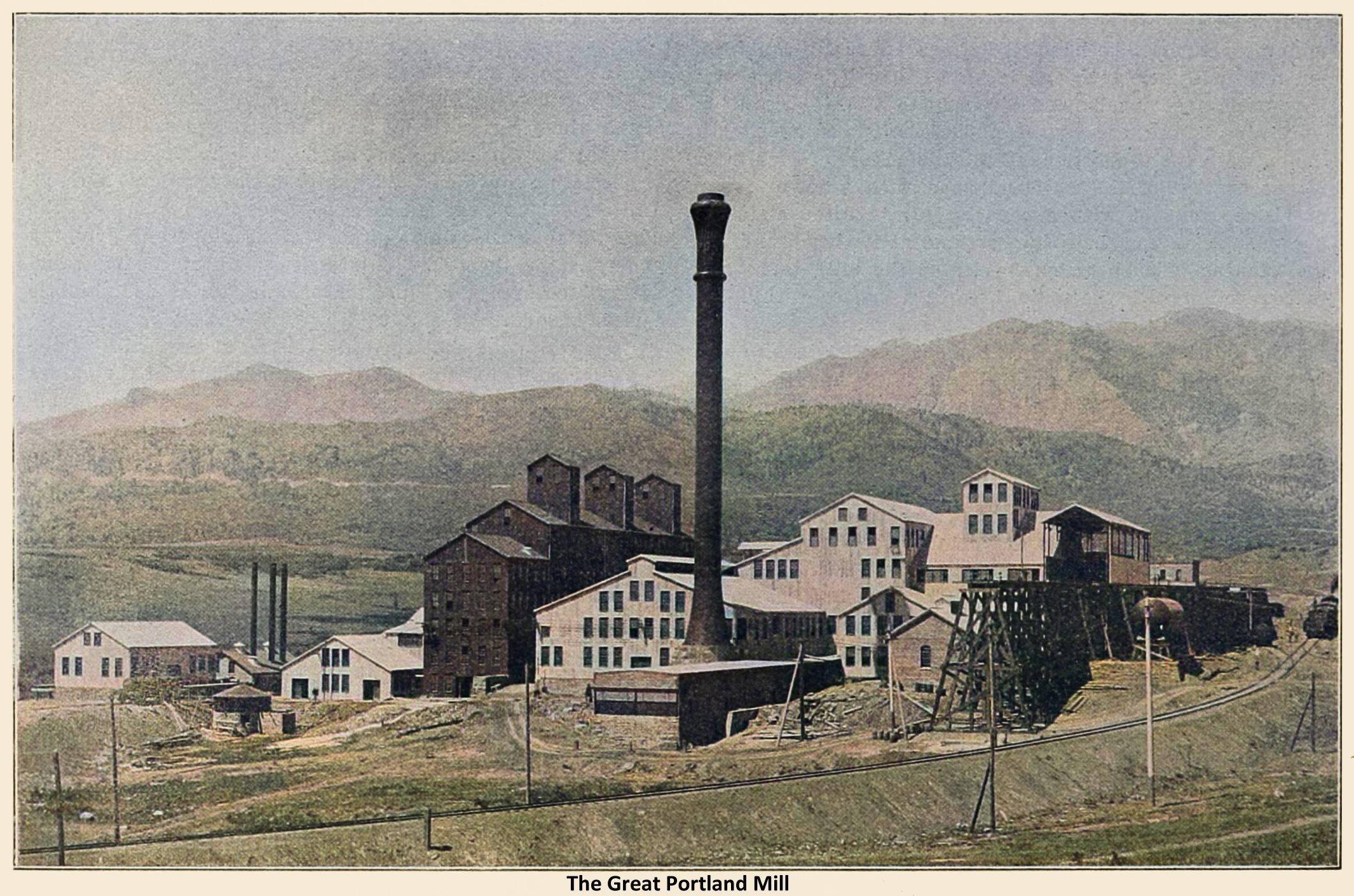

With this end in view the Portland Gold Mining Co. has carried on extensive experimentation, and we hope that a brief description of some of our experiences may be of interest.

Fine grinding in cyanide solutions followed by agitation and filter pressing was first tried, but difficulty in dealing with the stubborn sylvanite was experienced, so that our efforts were naturally directed toward the finding of a solvent for tellurium. We found, after experimenting along these lines, that the tellurium yielded to some extent under the action of oxidizing agents, and after trying various acid mixtures we resolved to find an alkaline solvent: the most successful ones were the alkaline per-sulphates. alkaline hypo-ioditcs, and cyanogen iodide.

The chemical behaviour of the alkaline per-sulphates is little known to metallurgists. They are not only solvents for tellurium, but their action when used in connection with cyanide solutions is extremely interesting. When thus used they act as slow oxidizers or depolarizers, thereby greatly increasing the dissolving power of cyanide solutions and when used in small proportions. 1 lb. to 10 lbs. per ton of solution, they do not destroy the cyanide to any great extent.

We have done a good deal of theorizing regarding the chemical action of these substances, especially when used in connection with cyanide solutions. When in solution alone, they act as strong oxidizing agents, as follows:

(NH4)2S2O8 = (NH4)2SO4 + SO2 + O2

But when mixed with cyanide solutions, their oxidizing influence is greatly retarded. In view of this fact, together with results obtained in small tests, we are of the opinion that the per-sulphates, if produced at a low cost, could be generally used in cyaniding as oxidizing agents. They are quite stable compounds, and when mixed with working cyanide solutions would oxidize reducing agents, thus greatly aiding dissolving efficiency, precipitation, etc.

A recent article, "Cyaniding of Silver Ore in Mexico," written by Mr. W. A. Caldecott, brings to mind a possible field for these substances as a means of dealing with the reducing agents, which this article states are a great source of trouble. We have also discovered that ammonium per-sulphate is a good solvent for silver, but to what extent this property can be applied in ore treatment has not been determined.

We have made the following few small tests on the solutions from our tailing mill in the endeavor to find out the effect of per-sulphates upon cyanide solutions when used as oxidizing agents.

Three assay tons of blanket concentrates which assayed 108 ozs. per ton were put in each of six bottles; in each bottle were poured 262 cc. of our regular 1-lb. tailing mill solution; this made a three-to-one pulp, and 10 lbs. of lime per ton of ore were added. To the first three bottles, respectively, we added 0.1 lb., 0.25 lb. and 0.5 lb. of ammonium per-sulphate per ton of ore; the last three bottles being left as straight cyanide treatment.

All the bottles were well shaken and stood over night.

| Cyanide consumed per ton of ore. |

Ammonium per-sulphate added per ton of ore. |

Solution Assay Value. | |

| No. 1 | 0.55 lb. | 0.10 lb. | 4.13 oz. |

| No. 2 | 0.55 lb. | 0.25 lb. | 4.35 oz. |

| No. 3 | 0.55 lb. | 0.50 lb. | 4.46 oz. |

| No. 4 | 0.60 lb. | None. | 3.54 oz. |

| No. 5 | 0.55 lb. | None. | 3.82 oz. |

| No. 6 | 0.55 lb. | None. | 3.72 oz. |

From these experiments you can very readily see the effect of the increased dissolving efficiency obtained when an oxidizing agent is used, the consumption of cyanide being practically the same as the straight cyanide treatment.

Taking the average solution assay 4.313 ozs. of the three bottles to which per-sulphate had been added, and comparing the average solution assay 3.693 ozs. of the three bottles where no per-sulphate was added, and multiplying each average by three (as three to one pulps were used), we obtained a difference of 1.86 oz. extracted by the addition of small quantities of per-sulphate.

The low extraction obtained in either case will be a cause of surprise, but it is a good example of the refractory nature of our gold. This material had passed through a roasting furnace, through chlorination barrels, over the Wilfley tables, then ground to 60-mesh in a 1-lb. cyanide solution, then caught on blankets, and was merely used in these experiments on account of its value to make a decided case.

As stated before, alkaline per-sulphates are solvents for tellurium, and when mixed with cyanide solutions completely dissolve the telluride of gold. We have made several bottle tests on ore, using a solution of alkaline per-sulphate as a preliminary treatment, followed by a cyanide solution, the object being to first dissolve the tellurium, leaving the gold in a condition susceptible to cyanide solutions, but with poor results on account of reasons explained later, except where extreme amounts of per-sulphates were used.

We have also tried a treatment using the alkaline per-sulphate and the cyanide together in the same solution, dissolution of the tellurium by the per-sulphate and the dissolution of the gold by the cyanide going on simultaneously, but with uneconomical results due to reasons explained later.

Alkaline per-sulphates, like some other oxidizing agents, liberate iodine from potassium iodide in an alkaline solution, the liberated iodine combining with the alkali present to form alkaline hypo-iodites, which compounds we have found dissolved tellurium; we, therefore, conclude that the addition of potassium iodide to a solution of per-sulphate plus cyanide would form this tellurium dissolving compound, while the cyanide present would take care of the gold, the two working simultaneously.

For a long time we were led astray in our experiments. We had found that an excess of alkali in a solution of potassium cyanide plus potassium iodide plus alkaline per-sulphate greatly increased the solubility of gold leaf; test after test with good excesses of alkali was tried, believing that the solution that had the greatest dissolving efficiency upon gold, would have the greatest efficiency upon the telluride of gold, and working on the theory, that the liberated iodine formed hypo-iodite, which dissolved the tellurium, the cyanide present dissolving the gold, we could not see wherein an excess of alkali would be injurious; but we invariably failed to obtain a good tailing, unless we used an uneconomical percentage of per-sulphate.

Finally, we discovered that cyanogen iodide was an exceedingly good solvent for the telluride of gold, and the idea occurred to us that it was possible to form cyanogen iodide in a solution of this kind by the action of the per-sulphate upon the potassium iodide, the liberated iodine combining with cyanide forming cyanogen iodide:

KCy + 2I = ICy + KI.

Knowing of the similarity existing between cyanogen iodide and cyanogen bromide, and having some knowledge of the cyanogen bromide process, we worked upon the theory, that the existence of cyanogen iodide depended upon the absence of excessive quantities of alkali. In following this out we found that we invariably obtained good tailings, even with very weak solutions.

A solution of 1 lb. of cyanide, plus 1 lb. of potassium iodide, plus 3 lbs. of alkaline per-sulphate per ton of solution, in a pulp of three solution to one of ore, with 4 lbs. or 5 lbs. of lime per ton of ore, gave us on 1-oz. ore, ground to 100-mesh, tails of less than $1, with a consumption of cyanide of about 1 lb. per ton of ore.

But we found that our solutions after leaving the ore and standing in contact with the air, lost their cyanide, a very hard thing to believe, as the same solution before being applied to the ore would stand in a beaker indefinitely with a very little loss of cyanide. Even when in contact with the ore in a bottle, this loss was not excessive, but when separated and left to stand, the cyanide in some cases disappeared rapidly.

We discovered that this loss was more pronounced when treating heavy sulphide ores; and we are led to believe that it is due to the formation in our solutions of Na2S4O6. Sodium thio-sulphate, Na2S2O3, being formed by the action of the per-sulphate upon the pyrite, is probably further oxidized to Na2S4O6.

2Na2S2O2+I=2NaI+Na2S4O6.

When the solutions are in contact with the ore, the reducing action of the ore aids in overcoming oxidizing influences, but when separated, the oxidation becomes more violent.

The action of the air seems to have a marked influence on the cyanide destruction, as at any rate, a decided difference in consumption is noted in using closed and open agitators. However, we find that on passing the solution through the zinc boxes, the deterioration of the cyanide is stopped, due undoubtedly to the reducing action encountered there.

We have experimented in a small way upon the manufacture of sodium per-sulphate by the electrolysis of salt cake, and obtained a product which, when used in bottle tests, answered very well, so that it might be produced on a large scale at a reasonable figure.

Potassium iodide, although an expensive chemical, would remain as such in the solution, the per-sulphate causing it to give up its iodine, this iodine combining with the cyanide to form cyanogen iodide, or with the alkali to form an alkaline iodide, or alkaline iodate. but always finally reverting back to an alkaline iodide, as any iodate formed would be reduced to iodide in the zinc box.

Cyanogen iodide is certainly a wonderful solvent for gold tellurides, and its production by this method we believe presents a possible field for ore treatment. We understand that in the practice of using cyanogen bromide as a solvent, one of the troubles other than its cost, is its rapidity of action, as it remains as cyanogen bromide only for a limited period, and does not act sufficiently long to cause the dissolution of the telluride of gold.

It can, therefore, readily be seen that if it were possible to produce it in a similar manner to the one described, a much weaker solution constantly in contact with the ore, would have a decided advantage.

In an attempt to present this in a more lucid manner we add the following summary; our object being to treat the finely crushed ore by one of the following schemes:

1. A preliminary treatment by an alkaline per-sulphate, followed by a treatment with a cyanide solution.

2. A treatment by a solution containing both alkaline per-sulphate and potassium cyanide.

3. A treatment by a solution of an alkaline per-sulphate, an alkaline iodide, and potassium cyanide, contained in one solution.

In the first, we find that it requires a strong solution of per-sulphate to obtain a good tailing.

In the second, our object was to produce an alkaline hypo-iodite; by so doing we would have an alkaline per-sulphate and an alkaline hypo-iodite acting as tellurium dissolving substances, and potassium cyanide acting as a gold dissolving substance, but we have found that it requires a strong mixture of the above to obtain the extraction.

In the third, our object was to produce cyanogen iodide, and not to depend directly upon any of the ingredients other than cyanide and cyanogen iodide as solvents.

As stated in the first portion of this paper, the refractory nature of these ores is due largely to the occurrence of gold in combination with tellurium, etc., and also to the association or encasement of these gold tellurides in pyrite. We have found that with any of the three schemes our dissolution was perfect, even with weak solutions when working on ores where part of the values was associated with the pyrite, we experienced difficulty with the first two schemes; but the third invariably gave good tailings.

Concentrates are usually a very refractory material to handle, even when the gold occurs as metallic gold associated with pyrite. But in this case we have, instead of metallic gold, the refractory telluride of gold associated with the pyrite, and the problem which confronts us can readily be appreciated; although the oxidizing agents, per-sulphates and hypo-iodites as used in the first two schemes act very well upon the crystals of sylvanite when coming in contact with the sylvanite only; associated with the reducing pyrite, their function is to a great extent destroyed.

NOTE 1—Journal of the Chem., Met. & Min. Soc. of S. Africa, May, 1909.

NOTE 2—"Cyaniding of Silver Ore in Mexico," can be found as two chapters in the Mining and Scientific Press issues of March 28, 1908 and May 2, 1908, at the HathiTrust Digital Library Site.

_cc-crpd-enhanced-colored.jpg)