-> My Collection, Also on

-> the Internet Archive Site; Link to article.

New Year Edition 1903

(pages 83-84)

Source had only the large bottom pic, I added the smaller previews from my collection

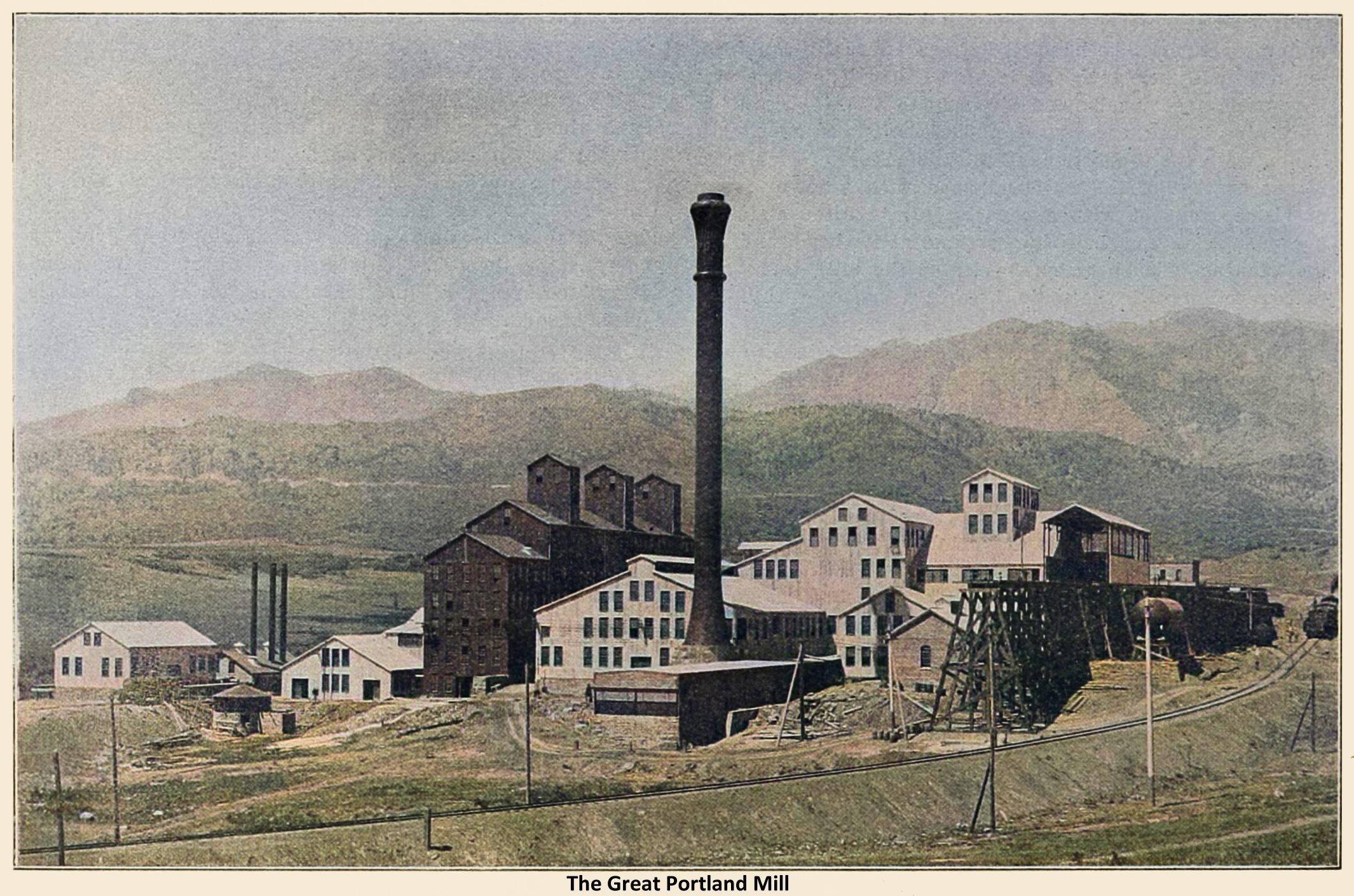

So noiselessly and unostentatiously does The Portland Gold Mining Company work, that few people at large are aware of the interesting fact that it owns the finest, best appointed and most scientifically constructed chlorination plant in the world.

The cost of this institution, which is the consummation of technical skill and energy, was $500.000. A half a million dollars is a large sum of money for a gold mining company to expend, but that the management of the Portland acted wisely, is shown in the great saving to the stockholders of the company, and the corresponding increase in dividends and values.

This was an expenditure which made money for the company, besides enhancing, in large degree, the real value of the stock.

The mill was absolutely required for the business of handling the many thousand tons of ore which the company is unearthing and bringing to the surface day by day. True, such an enterprise as the mill, as well as that of the mine proper, must be handled by men unusually equipped, not only with scientific and technical knowledge, but who have executive capacity and foresight to a large degree.

Mining is an exact science, and while it is entirely legitimate, when the proportions of the business is of such magnitude as that of the Portland, men with a broad range of vision, and yet with a capacity for infinite detail are needed. Such men had the Portland at its head, and the undertaking of such an enterprise as the mill, to be run in connection with the mine, became a matter within the range of possibility.

The Portland mine produced about 100,000 tons of ore last year, and 77,000 the previous year. In handling such a tonnage, there is a fine chance to make a splendid saving and the saving will add millions in time to the revenues of the company.

With such an enormous output as that of the Portland, there were thousands of dollars of profit in handling the ores, and the custom mills and smelters received that fortune.

Instead of paying out that sum, the sagacious managers decided to make an investment of half a million dollars, and turn the profits that the custom mills and smelters were receiving into the pockets of stockholders. They would rather do without a lump sum now, in order to put many times that much money into their pockets in the course of time.

This is foresight and wisdom, but it is at the same time courage and confidence on the part of the brainy men at the head of the great concern.

The Portland mill, which is located about a mile west of the heart of the city of Colorado Springs, is a favorite place, now, for pilgrimage of educated mining men who come West. Not only the magnificence of the plant, but the skill with which it has been erected, is an inspiration to those who see and appreciate. Besides, it is an incentive to thousands of other mine owners who have for years been paying fortunes to the custom mills and smelters.

Many have been and looked upon this magnificent enterprise, and gone away determined if possible to go and do likewise. It has sown the seed of endeavor and gigantic effort in the hearts of many who before would not have dared to entertain such a stupendous thought.

It has been estimated that a trainload of 750 cars, six miles long, was needed to haul the material to the site of the new mill.

One-tenth of the train, or seventy-five cars, carrying 1,340 tons of structural steel, was taken up with the machinery and other equipment of the plant.

In preparing the foundations, 28,000 cubic yards of excavation had to be made, and 6,666 perch of stone were utilized in making them.

One million brick were used, yet as one goes through the various departments he hardly notices any brick anywhere, except in the furnace room and office building.

A million and a quarter feet of lumber was utilized, but the plant is absolutely fire-proof, many of the shops and buildings being of corrugated iron.

The enclosed floor space of the plant is 190,000 square feet, or an area equal to about two city blocks, counting out the streets and crossings.

Of the flooring, 40,000 square feet, or about one-fourth of the whole, has been put under cement and asphalt.

The necessity for this is interesting, as it shows the acute stage of perfection to which the creators of the mill have arrived.

The cement and asphalt are a necessity, because of the dust which arises during the various stages of grinding and reducing the ore. This dust is one of the most important features of a chlorination mill, for it is a subtle carrier of gold.

It is estimated that the dust arising at any point of the process contains about four times the amount of the values which the raw ore contains at that stage. The dust problem, so long disregarded in many chlorination mills, has received the most careful consideration at the hands of the alert Portland management and experts.

These floors, landings and platforms are swept and re-swept many times a day, and the wisdom if it is shown daily in one department, where it costs $10 a day for sweeping alone. But the operation pays, as the dust gathered up yields about $50 a day that would otherwise be entirely lost.

At the Portland plant there are two units or digits, the crushing and roasting departments in one building, and the chlorination and the precipitation departments in another. All other departments are ancillary to these two main ones. The process of chlorination of ores is simply to grind them, so that the sulphur may be roasted out, after which the pulp is subjected to chlorine gas, generated under water, when the gold is taken out of the rock, forming chloride of gold in solution.

The gold is transformed into this liquid state simply because it is the most convenient way to carry it to the next stage of operation, the precipitation or breaking up of the chemical combination of chloride of gold, after which the sulphide of gold (the new form taken on by the gold) is collected, as a black powder, on canvas sheets, and these are burned up in the receptacles about the size of a large bread pan.

In this process, heat of immense intensity is required, so the pans are placed in refining muffles, where a temperature of 2000° Fahrenheit is maintained, that drives off the sulphur, leaving the gold in the bottom of the pan.

The gold is collected from these pans, put into refining pots of still greater heat, which reduces the metal to a molten state, and if by chance there is any dross, it rises to the surface of the mass as a scum, is scooped out, reburned, and any values therein saved.

So it is seen that very little gold escapes the eagle eyes of the Portland mill. The plant has installed the latest and most improved machinery, and it has the benefit of the very best methods known to the science.

The construction work of the mill was finished last May.

Sampling was shortly started to try and demonstrate the machinery.

In the latter part of June the first ore was run through the entire process. The mill has been running splendidly ever since.

Owing to the decrease in the supply of fuel oil for the roasters, for which they are adapted, the amount of ore handled has been decreased. The apparatus in the mill has steadily improved, and is now in first-class condition, and with the fuel situation straightened out, very satisfactory results will be obtained.

The various departments of the mill have proven that they are entirely capable of handling 300 tons of ore a day, for which the mill was originally intended.

The construction of the mill marked one of the most important developments in mining in the Cripple Creek district, so pregnant with large endeavor and wise foresight.

The construction of the Portland mill has been a benefit wide and broad. While the stockholders have been the direct beneficiaries, it has resulted to the betterment of others, in that it was responsible for the reduction of charges on the part of custom mills and smelters.

The Portland people had given the large mining companies of the state an example of what could be done if thought and energy were brought to bear upon a difficulty.