I included a slighlty rewritten statement from the first article, I also added the map from my collection, in addition to including a Sanborn Fire Insurance Map, and a 2nd image not in source.

This is the concluding third article of those laid before those interested in the treatment of gold ores, a serie giving an accurate description of three gold mills recently erected in Colorado, dealing with the subject, more especially from a mechanical point of view.

Accurate figures of labor required, and the cost of operating these plants, is given, also a brief statement of the metallurgical results. The Page Process Mill in Florence and the Delano Mining & Milling Company, of Boulder was the other two mills.

The mills described embrace a number of interesting features, and as each plant has been found to work well, both mechanically and metallurgically, from the time it was put into operation, it is hoped that those interested in the construction of similar mills may be able to derive some helpful information from these descriptions.

In considering the subject of mill construction from a mechanical standpoint, it may be well to state that owing to economic conditions, the question of low first cost is often one of great importance; and for this reason the design and general construction of such plants may seem to lack in the features of permanency and ultimate economy.

And it is no doubt true that a greater expenditure on the first installation for better buildings, and more liberal proportions to all parts of machinery, would be an ultimate economy, provided the plant as first designed fully meets the requirements.

This is seldom the case with gold mills, and most companies prefer to test their ores at as small an outlay as possible; but where the process, ore supply, and economic conditions have been fully exploited, the question of permanency should receive full consideration.

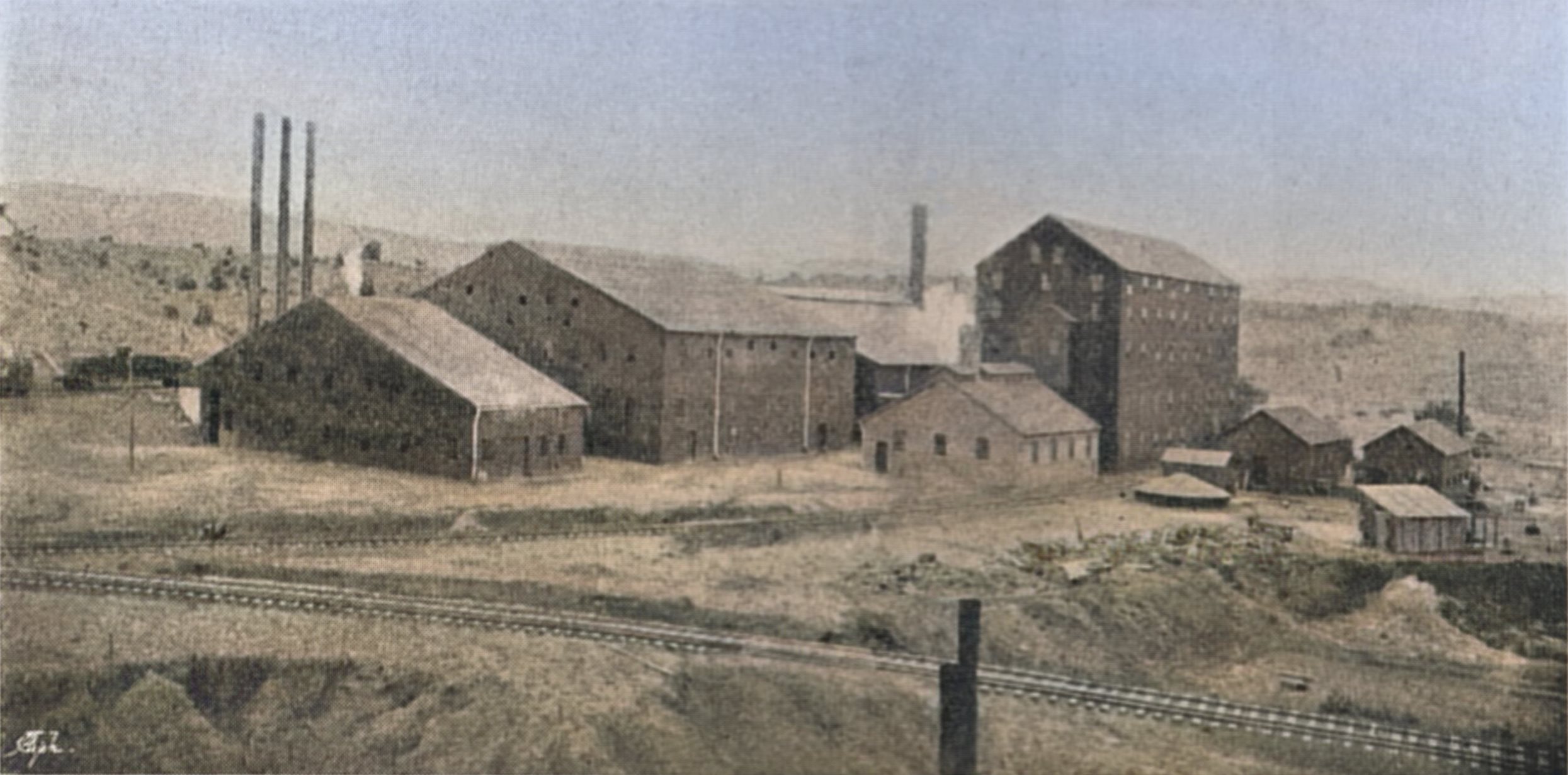

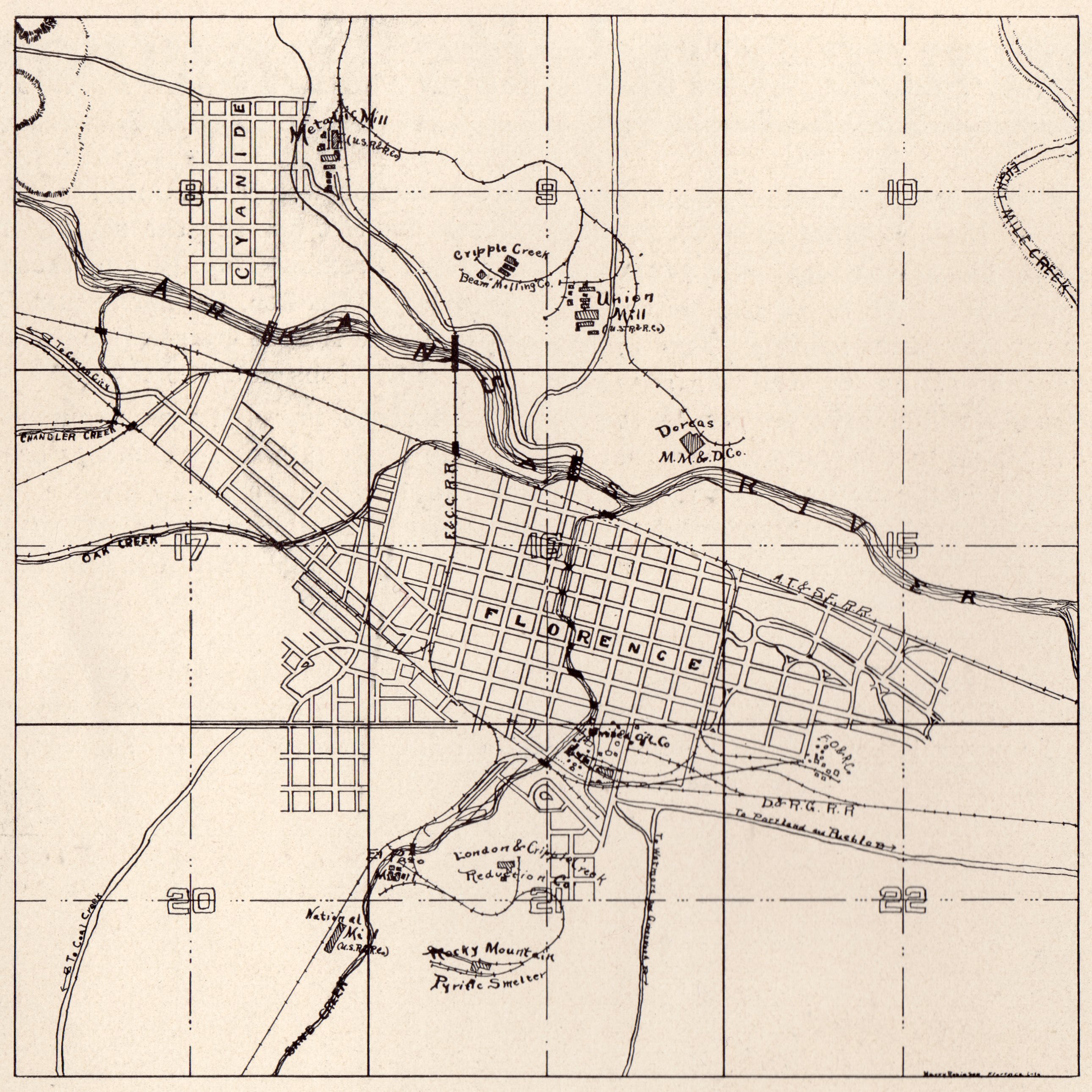

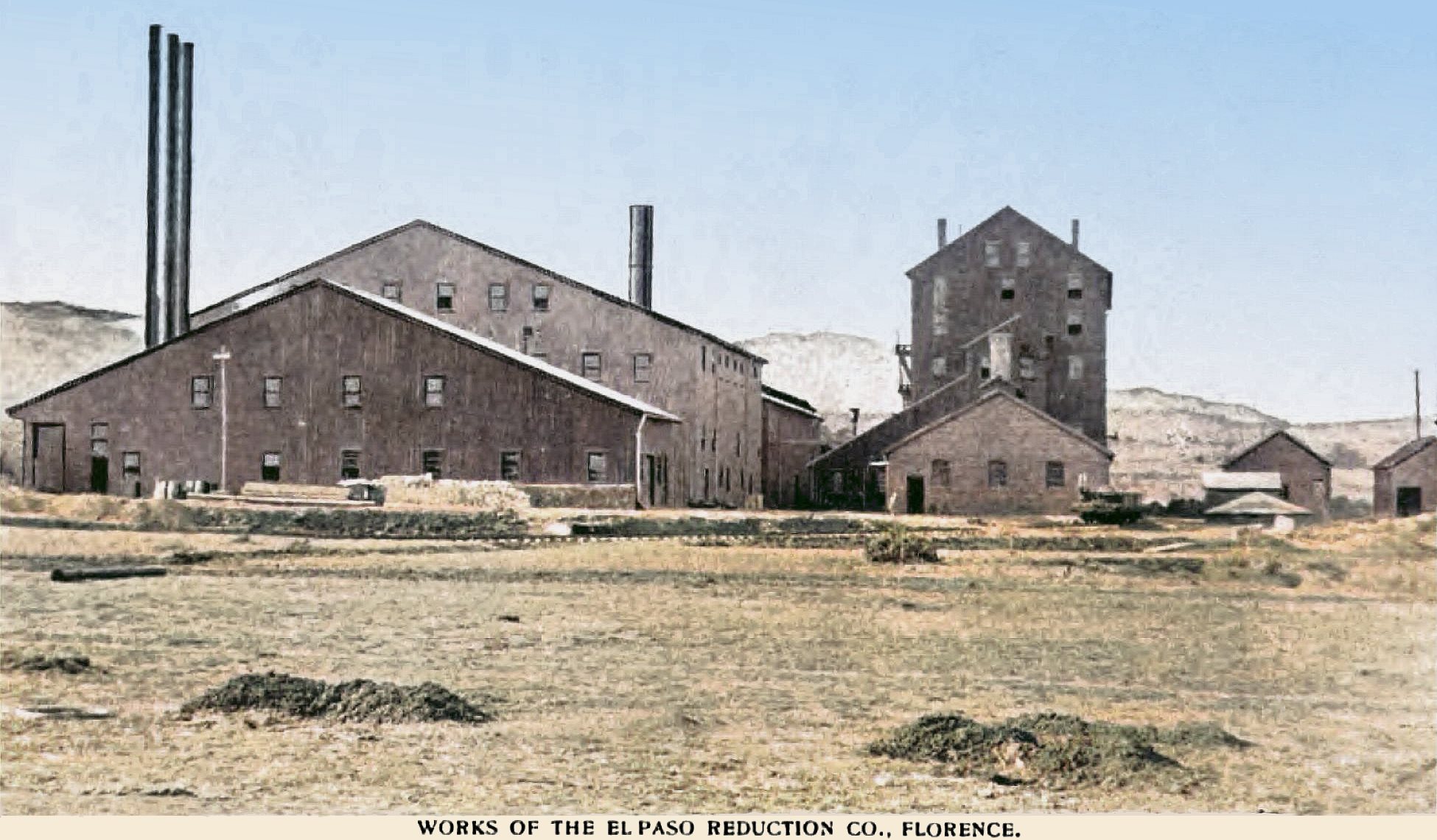

THIS is a regular barrel chlorination mill using the "Davis" charcoal recovery system, and was built for the treatment of ores from the Cripple Creek mining district. The mill was located south, and east, of the Depot area of the F. & C. C. and the Denver & Rio Grande, as a branch east, then north, off its Coal Creek Branch.

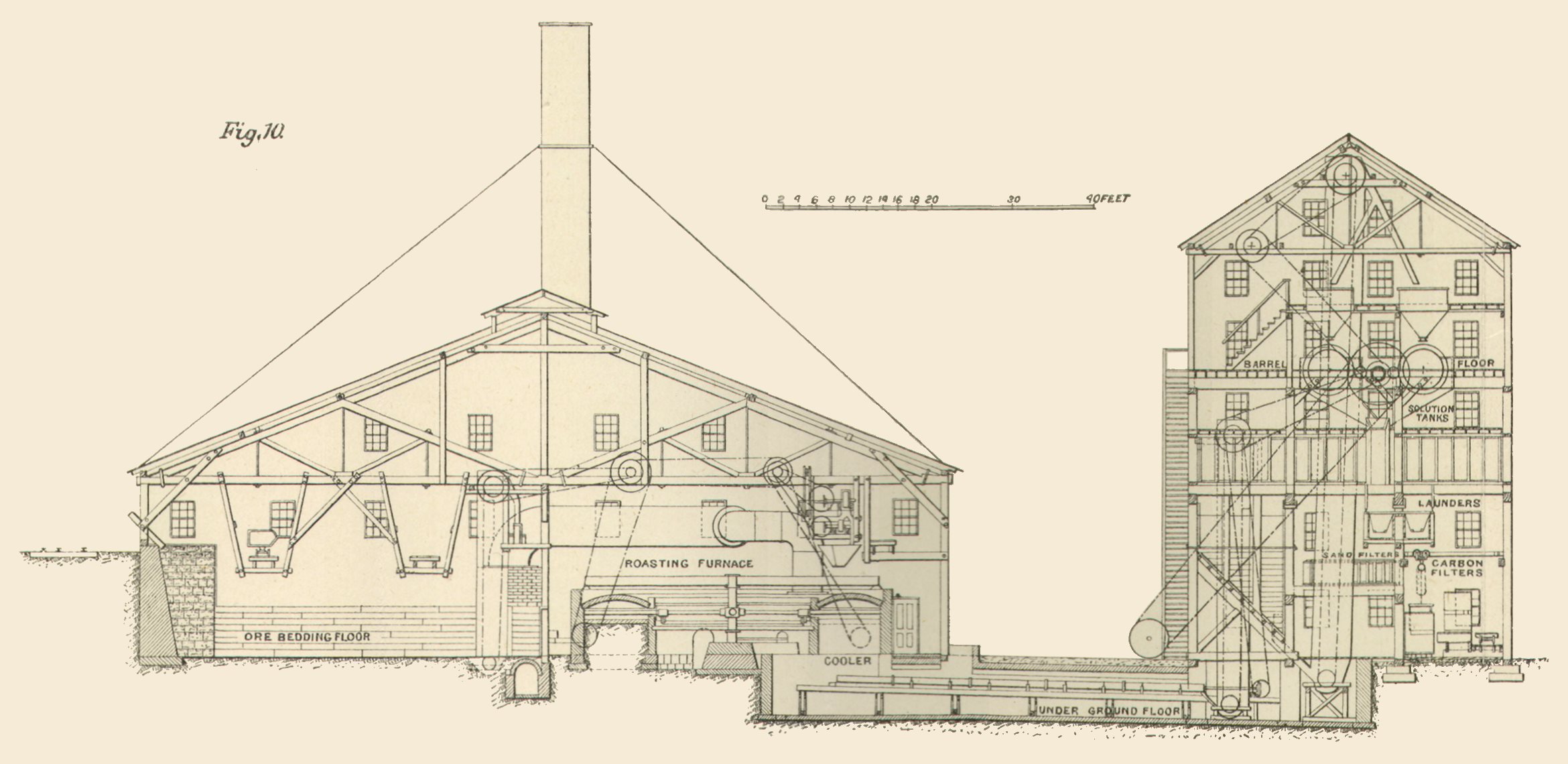

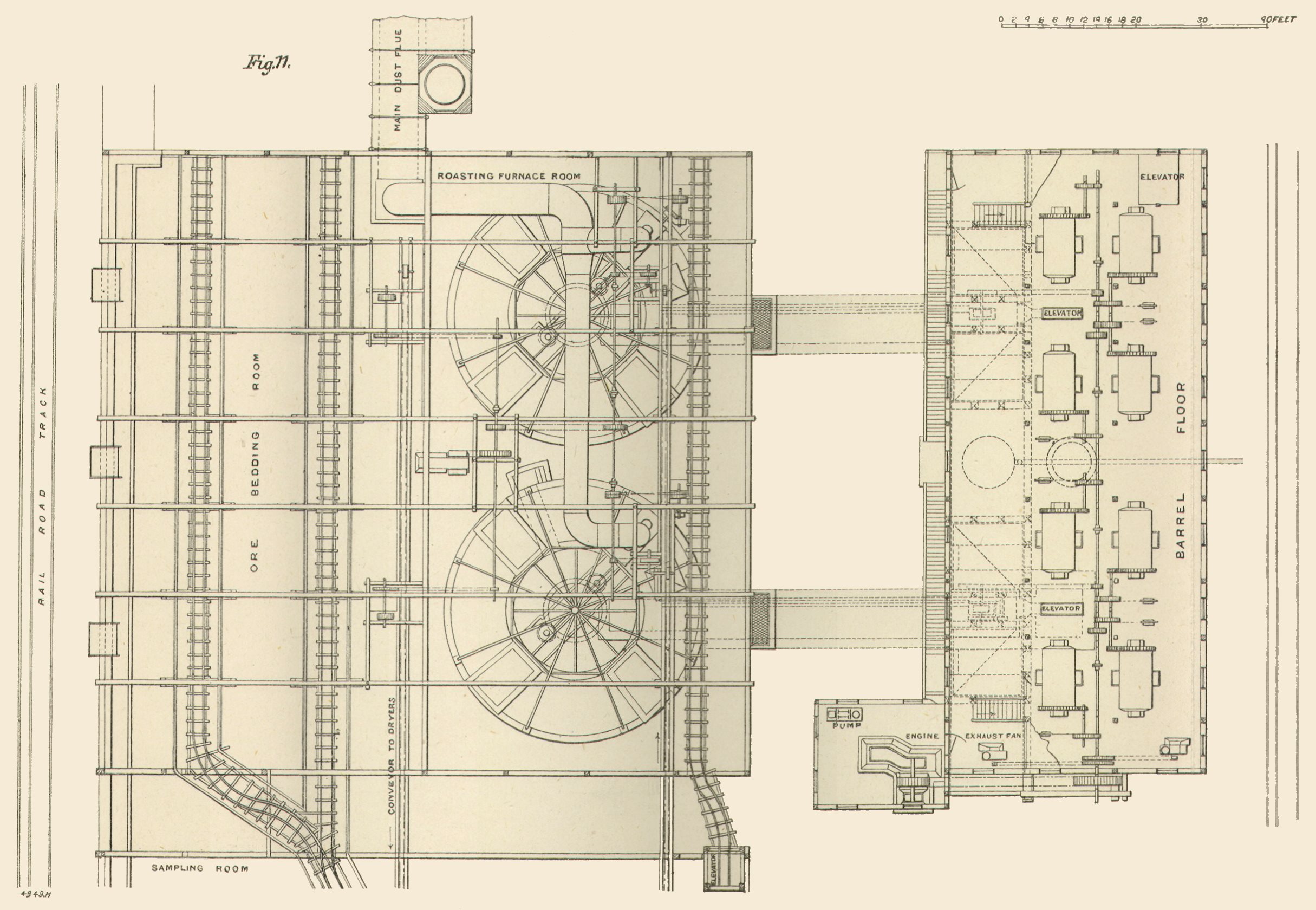

Being of larger capacity than those already described, it was deemed advisable to construct separate buildings for the various departments, thereby securing an abundance of light and a greater accessibility throughout.

The buildings are constructed on the same level, the ores being delivered on an elevated track at the south end of the mill. (See our two-page plate, and also page 236).

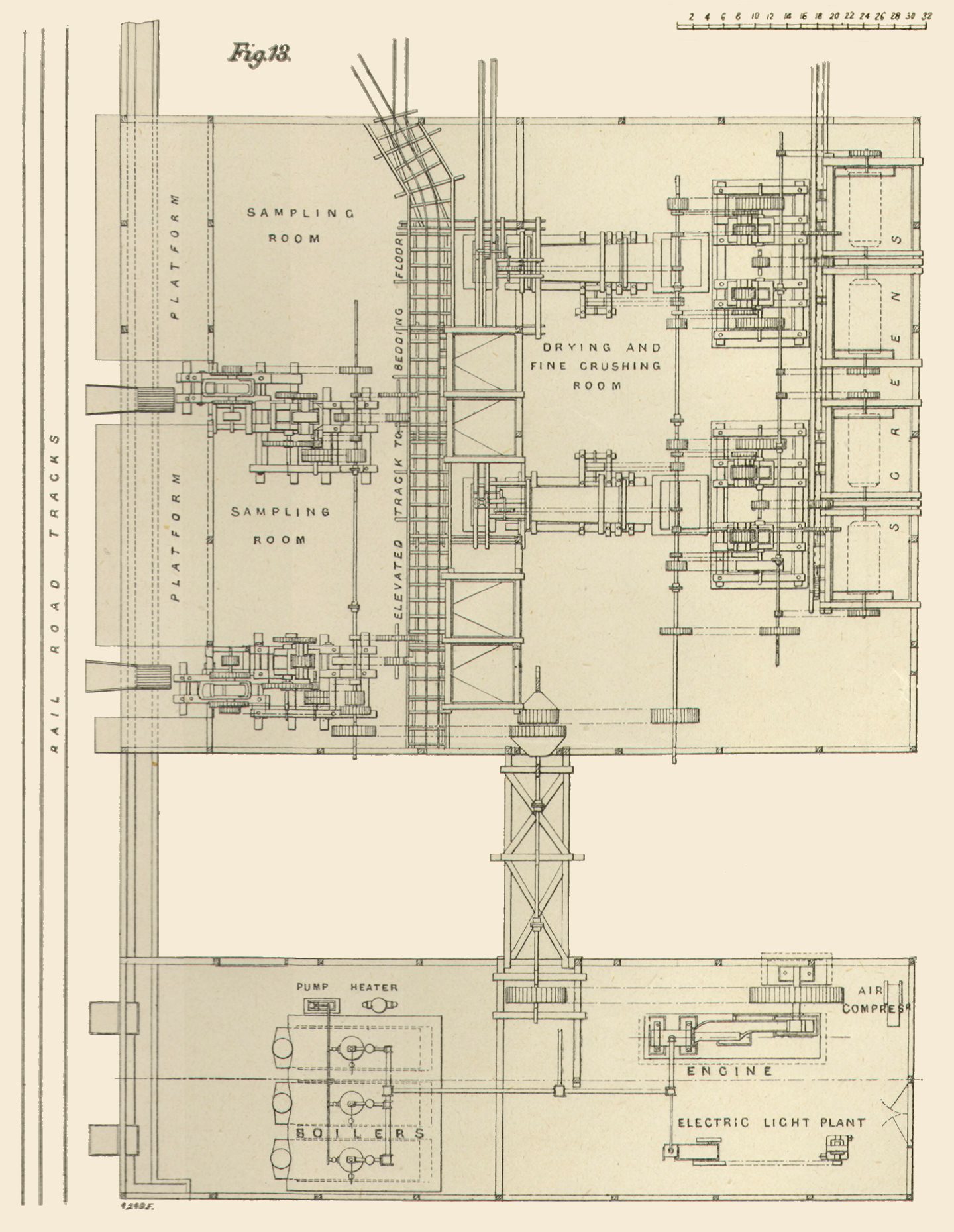

Starting from the east end we first encounter the power plant (Fig.9 and Fig.13). This is contained in a building 100 feet by 30 feet divided to form an engine and boiler-room. In the boiler-room are three 60-inch by 16-foot horizontal return tubular boilers with a heating surface of about 1100 square feet each. These boilers are set in one battery, each being provided with an independent smoke stack.

The fuel used is residuum from the distillation of petroleum burned as a liquid, the fireboxes being specially constructed for its use. The residuum is delivered at the works in tank cars from the oil refinery which is about a mile distant, and is pumped into an oil storage tank 10 feet in diameter by 30 feet long, set on the hill above the works. This tank sits high enough to give a free gravity flow to all parts of the works where fuel is used.

The storage tank is fitted with a small coil, through which the exhaust steam from the pumps is passed for the purpose of keeping the residuum sufficiently hot and fluid to flow freely. At the normal temperature it is quite thick, and to obtain the necessary fluidity, a steam pipe is carried in close contact with the residuum pipes, both being wrapped in the same covering. This system is followed wherever fuel is used in the works. In the main engine-room there is a 16-inch by 42-inch high-pressure Corliss engine running at 75 revolutions per minute driving to the main countershaft, from which all the crushing machinery is driven. There is also an 8½-inch by 10-inch high-speed engine, and a 12-kilowatt 110-volt generator for electric lighting, and a 6 inches by 6 inches by 6 inches air compressor for pumping acids.

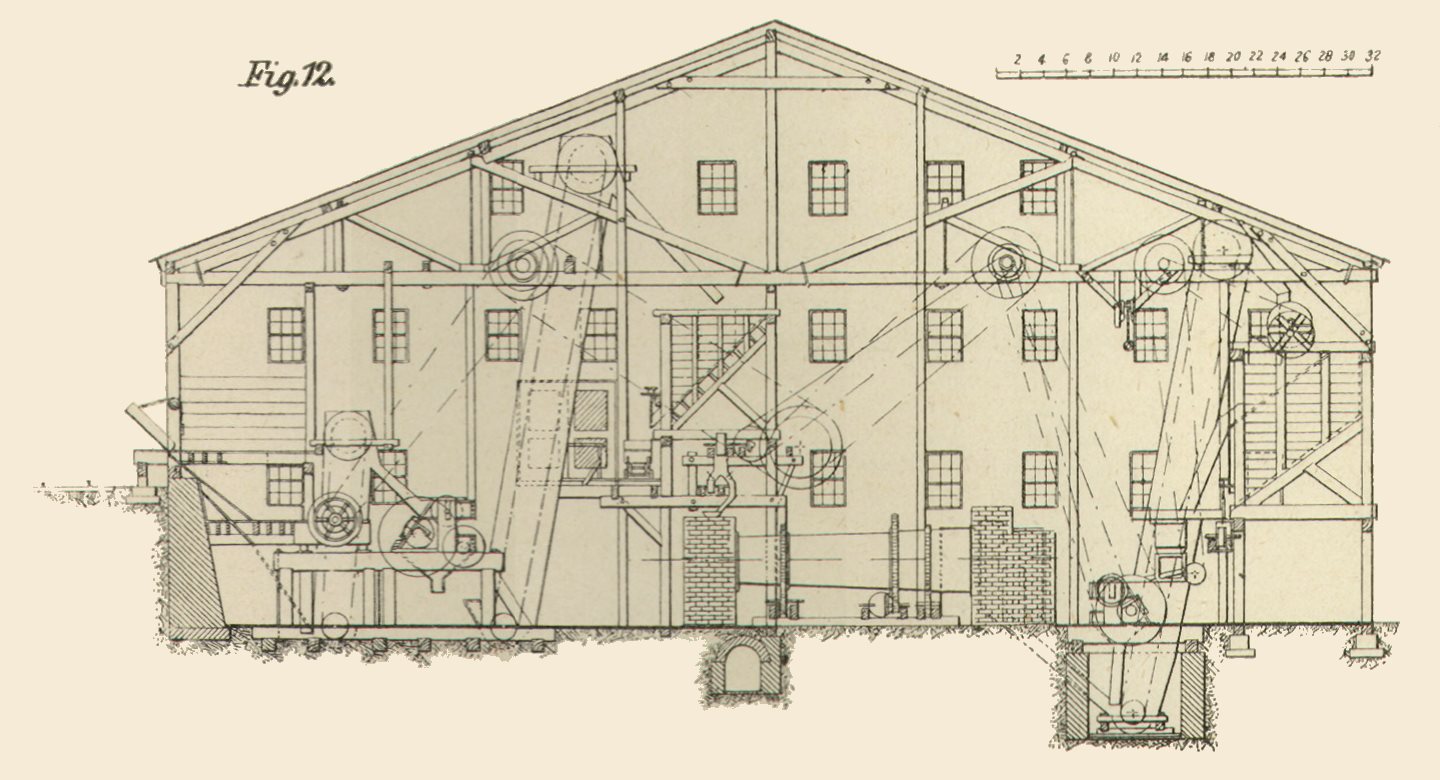

The crushing mill shown (Fig.12 and Fig.13) adjoins the engine-room on the west, with a passage-way of 26 feet between the two buildings. This building is 100 feet wide by 80 feet long, with a clear head room of 29 feet to the underside of the roof trusses. The ore is delivered to the sampling machinery from an elevated track 12 feet above the mill floor, the front of the building having a platform 14 feet wide, 3 feet 3 inches above the track, extending the full length. The mouths of the rock breakers are set 6 feet below the level of this platform, and have chutes leading to them with grizzlies in the bottom of each, by means of which the ore can be discharged directly from the cars to the crusher without wheeling. The platforms are provided for the reception of ore which cannot be taken directly to the mill.

The crushing machinery in the sampling department comprises two complete and independent sets. The set at the east end of the mill has one 9-inch by 15-inch Blake breaker, and one set of 16-inch by 36-inch rolls working together. The breaker is fed by hand with ore delivered from the cars as above described. All the fine material which passes the grizzly, together with the product from the crusher, is elevated and fed to the 36-inch rolls, the rolled material dropping to the floor in a heap where it is sampled by hand ; one-tenth being taken as a sample, the balance being shovelled into the boot of the elevator which delivers into the sampled-ore bin shown on the drawing. After a lot has been run through, the sample is coned and cut down to the desired size. The sampled ore from the elevated bins is loaded into cars and trammed to the bedding floor in the adjoining building.

No. 2 sampling plant is the same as No. 1, except that the breaker is of the "Dodge" pattern, size 11 inches by 15 inches, speed 225 revolutions per minute. It was deemed advisable to install a "Dodge" breaker to take the extremely hard dry ore, while the ''Blake" type of machine was considered better suited for ores containing a large percentage of moisture. To follow the ore in its course through the mill, the bedding floor will next be described. This occupies about half the floor space in the building adjoining the crushing mill to the west, and is shown in Fig. 10 and Fig.11 of our two-page plate. This building, which also contains the roasting furnaces, is 95 feet by 100 feet by 21 feet clear height.

The south side, or that next the elevated tracks, is set apart for the bedding of ores, the ore being trammed to it by the elevated tracks shown, which are 12 feet above the floor level. The bedding floor is divided into two portions of about equal area, arranged so that a bed can be made up on the one, while the ore on the other is being run through the mill. The purpose of bedding the ore is to obtain a considerable quantity of material of as nearly a uniform value and character as possible. The ore, as it comes from the sampling mill, is uniformly spread over the entire area of the bed until a depth of 6 feet has been accumulated. By this means about 600 tons of storage is provided on each bed, or about 1200 tons altogether. The ore is handled back to the dryers and fine crushing plant in the crushing-room by means of a conveyor belt 12 inches wide made with pure rubber flanges on each edge, travelling at 100 feet per minute. The ore is delivered on to this belt by means of two bucket elevators, one for each bed, to which it is wheeled and shovelled. The 12-inch conveyor extends through to the No. 2 dryer where a dividing mechanism is provided, by means of which all the ore can be fed to No. 2 dryer; or all or any part of it may be passed to the No. 1 dryer at the will of the operator, a short belt conveyor 8 inches wide being placed to carry from the end of the 12-inch belt to the No. 1 dryer.

The drying furnaces are two in number, each being of the same general description as those described in connection with the Page Process Mill. These dryers are set with their discharge ends towards the fine crushing rolls and deliver into elevators in the roll pit, as shown. They are fired with residuum, the firing being done from the side of the firebox. The dried material is elevated to the screens, there being two of them to each dryer, each 4 feet in diameter, 9 feet long, covered with 14-mesh cloth made of No. 19 wire, and are set with their axes at an angle equal to a fall of 1 inches to the foot towards the discharge end. These screens are closely housed in with matched flooring, but have no dust-collecting apparatus in connection with them. Each screen delivers into a 30-ton bin constructed directly under it, the screened material being returned to the roll feeders, as already explained. Each screen bin is provided with two discharge gates, which deliver the ore on to an 8-inch belt conveyor delivering into No. 1 furnace feed hopper. At the end of this belt is a dividing apparatus similar to that described in connection with the dryers, by which all the ore may be fed to No. 1 furnace, or all or part of it delivered to No. 2 furnace, by means of a short 8-inch belt conveyor.

There are four sets of fine crushing rolls—size, 14 inches by 30 inches; speed, 45 revolutions per minute, belt driven—set over a pit 10 feet deep, and arranged so that each two pairs work as an independent unit, taking all the material from one dryer and the returns from two screens. The capacity of the fine rolls is found to be in excess of some of the other parts of the plant. The roasting plant consists of two 40-foot Pearce turret furnaces (Figs. 14 and 15, page 236) with 8-foot hearths, having a maximum capacity of about 65 tons per 24 hours of the class of ore treated. They are fired with residuum, each furnace being fitted with three oil-burning fireboxes, constructed directly over the hearth. In operation it is desirable to bring the heat in the ore up very gradually; and for this reason the two fireboxes next to the feed are fired lightly, a No. 2 "Reed" burner being used in each firebox. By the time the ore has reached the third firebox, it is then in condition to stand a high temperature without loss of gold. In this firebox two No. 2 burners are used, and a bright red heat is carried. The raw ore going to the furnace carries from 1.5 to 2.0 of sulphur. The roasted ore contains from 0.10 to 0.15 per cent. These furnaces are fitted with tubular cooling devices similar to that already described, a long spiral conveyor carrying the roasted ore through to the chlorination building.

The spent gases from the furnaces are carried by a sheet-iron flue to a brick dust chamber, shown at the east side of the furnace building. This chamber is 6 feet wide, 10 feet high, 100 ft long, built with 12 inches brick walls, with a chimney 6 feet in diameter, 75 feet high above the ground line. From the roasting furnaces the ore goes to the chlorination building, which is located north of the furnace building, and is shown in plan (Fig.9) and section (Fig.10). This building is 40 feet wide, 95 feet long, by 50 feet high to the lower side of the roof trusses, and is constructed with various floors, as shown. The ore is delivered by the conveyors into elevators which discharge into four storage bins holding about 30 tons each. The bins are provided with sliding gates, through which the ore is fed as required, into two long elevators; these distribute to the barrel hoppers on the top floor of the building.

The barrel or chlorinating floor (Fig.11) under the hopper floor is furnished with eight chlorination barrels of a capacity of 5 tons each, mounted similarly to those described in connection with the Delano Mining and Milling Company's mill, and geared to revolve 5 revolutions per minute, being driven from a shaft running the full length of the building. The driving is done by means of flat-face paper friction gears keyed to the shaft, so arranged that any barrel can be instantly stopped at the will of the operator. The barrels are 5 feet in diameter, 8 feet long inside, lined with 18-lb. and 24-lb lead, and fitted with filters as already described. Under the barrels are eight solution tanks arranged on one floor. They are rectangular in form, 6 feet deep, lined with 6 lb. sheet lead, and have a combined capacity of about 100,000 gallons. These tanks are closely floored over, and made as nearly tight as possible, to prevent the escape of gas. Under the barrel floor two ducts are formed connected to the solution tanks and to two large exhaust fans set on this floor. These fans remove the chlorine gas as it is given off by the solution, and deliver it by means of pipes, high above the buildings. Owing to the corrosive nature of the gas all these ducts and pipes are made of wood, and the fans are lead-lined inside. Under the solution tanks are two lead-lined launders 3 feet by 3 feet by 64 feet long, closely covered on top and fitted inside with lead-pipe heating coils suspended 1,5 inches from the bottom, by means of which the solution is heated to about 120 deg. Fahr. Immediately under the launders are five sand filter tanks 7 feet by 10 feet by 3 feet deep, lined with 6-lb. lead. These tanks have a filter in the bottom formed of screened sand, through which the solutions are allowed to percolate and become thoroughly clarified before passing through the charcoal filters.

On the ground floor of the building are the charcoal filters (Fig. 10), 20 in number, set in two rows of 10 each, the first row being set half the height of the filter above the second row. These filters are sheet-steel vessels 40 inches in diameter by 5 feet deep, lined with 6-lb. lead, and are all fitted with 2-inch lead hose connections. The vessels are filled with charcoal, ground to pass a four-mesh screen, and having all the fine dust screened out of it, the surface being covered with a perforated sheet of lead for distributing the solution evenly over the mass. Over these filters is a small hand-power travelling crane for moving, and an 18-inch gauge track on the floor level with a low truck is provided for transporting them to the burning-room. The ground floor of the building is of Portland cement, with the drainage from all directions towards a 6-foot by 3-foot cement-lined sink in the centre of the building. This sink is also filled with charcoal, so that should there be any leakage of solution from the tanks or pipes, it can be washed into the sink where the gold contents will be recovered on the charcoal.

The operation of the precipitating department is as follows:

The solution is drawn from the barrels into the tanks underneath them, where it is allowed to settle, the tanks being filled alternately. All the tanks are connected by rubber hose to one common distributing pipe of lead 6 inches in diameter. After the solution has settled sufficiently, it is drawn oft through this pipe into the launders, where it is heated and then drained into the sand filters. Passing through these any fine sediment is removed, and the clarified liquor is drawn off and distributed to the No. 1 row of charcoal filters. The solution is allowed to percolate through the charcoal, passing by means of a rubber hose from the No. 1 to the No. 2 filters, from which it flows to waste, all the gold having been deposited on the charcoal. Most of the gold is recovered in the No. 1 filters, very little remaining in the solution passing to No. 2. As soon as the charcoal in the No. 1 has become sufficiently charged with gold, the filter is set on the truck and transferred to the burning-room, the No. 2 filter opposite being put in its place, and a freshly charged filter put in the place which was occupied by the No. 2. The "Davis" system of charcoal precipitation has been in use for some years, and has proved itself to be a very reliable and economical method of dealing with chlorine solutions.

The machinery in this building is operated by a 14-inch by 13-inch centre-crank automatic engine, located at the south-east corner of the building, and driving directly on to the line shaft in the barrel-room. In the same room a 10-inch by 6-inch by 10-inch duplex steam pump is placed, which furnishes water under 50 lb. pressure for leaching. This pump is connected up directly to the water-supply system throughout the works, and can be used, in case of of need, as a fire pump. Part of the lower floor of the chlorination building is used for the storage of chloride of lime, this being raised to the barrel-room as required by means of an elevator. The sulphuric acid is stored in an open tank 20 feet in diameter by 4 feet deep, lead-lined, located on the opposite side of the supply track from the burning room. In connection with this tank a pressure tank 3 feet in diameter, 7 feet long, is set in an underground chamber, and connected to it by a 1¼ inches pipe. The pressure tank is filled by gravity from the storage tank, and the acid raised by compressed air to a small storage tank set on the barrel-floor, from which it is drawn off as required.

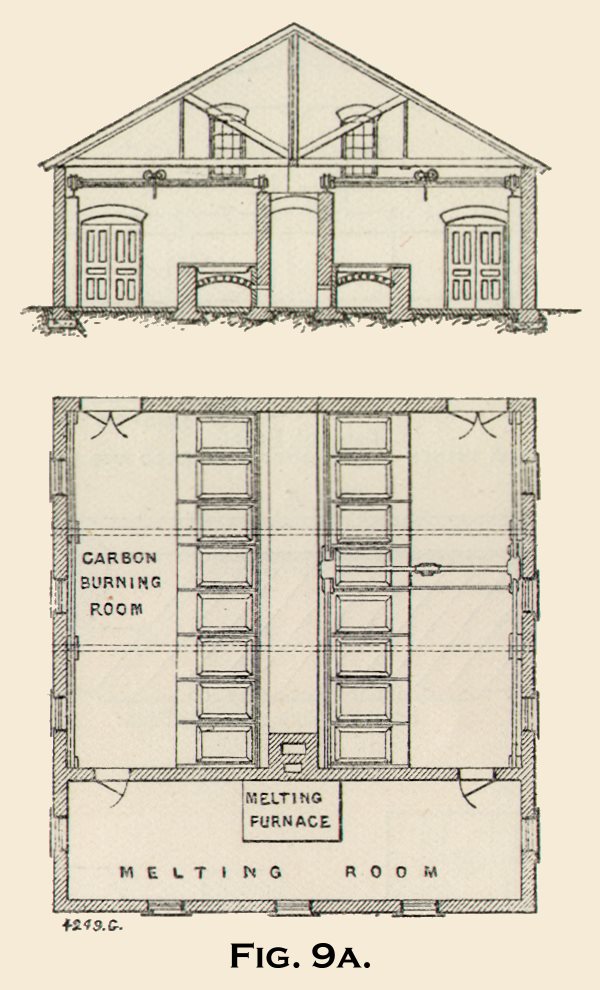

Adjoining the chlorination building on the east is the charcoal-burning room (as seen on section and floorplan at Fig. 9a), a brick building 40 feet by 43 feet, one storey high, divided into three apartments, two being used for burning the charcoal, and the third as a melting room, where the gold is run into bars. Each burning room is fitted up with a bench of burning pans set in a brick setting, fired from below with residuum, the burners being controlled from the central space shown between the two burning rooms. The flame does not come directly in contact with the iron pans, but plays on a firebrick arch of checker work, which serves to protect them from intense local heat. There are eight pans in each bench, each 3 feet 6 inches wide, 5 feet long by 7 inches deep, made of ⅞ inches cast iron, set 3 feet 6 inches above the floor line. The filters containing the charcoal are brought into the burning room on a low truck, and are lifted by a travelling crane high enough to empty the charcoal directly into the pans. Heat is applied gently from below, allowing the charcoal to burn off at as low a temperature as possible. The burning must be done at a low temperature, and in a still atmosphere, otherwise the mechanical loss of gold is heavy, After the charcoal has been consumed, the dust containing the gold is swept up and taken to the melting room, where the gold is run into bars.

In addition to the buildings described, the plant comprises the usual blacksmith and carpenter shops, which are independent buildings. The offices are located about 100 yards east of the mill, and are contained in a brick building 50 feet by 50 feet, divided into general office, 33 feet by 24 feet; private office, 14 feet by 15 feet; assay office, 24 feet by 24 feet; and laboratory, 24 feet by 24 feet There is also a fireproof vault and a fully furnished bathroom in this building. The offices as arranged are found to be very comfortable and convenient. In operation the works are found to have a maximum capacity of about 125 tons per day, and easily average 3000 tons per month. The working force in the mill for night and day running is about 45 men.

| Description | Per Ton of Ore Treated |

|---|---|

| Labour | $0.90 |

| Chemicals for all purposes | $0.53 |

| Fuel | $0.45 |

| Water | $0.05 |

| Wear and tear | $0.30 |

| Lubricating oils and supplies | $0.05 |

| Incidentals | $0.15 |

| Total | $2.43 |

The above figures are based on chloride of lime costing 2.40 dollars, and sulphuric acid 1.25 dollars per 100 lb. at the mill.

No salaries, interest on investment, general expenses, or depreciation are included in above cost.

The ores from the Cripple Creek mining district vary widely in character, as will be noted by the analysis given. The surface ores, as a rule, are quite thoroughly oxidised, but at depth sulphides are encountered, the values occurring as telluride. All of these, however, are very well adapted to treatment by chlorination, the varying constituents effecting the manipulation much more than they do the metallurgical results. The following are partial analyses of these ores:

| Description | Amount |

|---|---|

| SO2 | 63.46 |

| Al2O3 | 14.93 |

| Fe | 3.13 |

| S | 1.62 |

| CaO | 1.58 |

| MgO | Trace |

| K2O and Na2O (by diff.) | 15.28 |

| Assays, Au | 3.68 oz. per ton. |

| Assays, Ag | 0.32 oz. per ton. |

| Description | Amount |

|---|---|

| SO2 | 64.42 |

| Al2O3 | 14.82 |

| Fe | 4.54 |

| S | 2.36 |

| CaO | 1.20 |

| MgO | Trace |

| K2O and Na2O (by diff.) | 12.66 |

| Assays, Au | 1.68 oz. per ton. |

| Assays, Ag | 0.22 oz. per ton. |

| Description | Amount |

|---|---|

| Alumina | 29.94 |

| Silica | 63.13 |

| Lime | 0.70 |

| Iron oxide | 3.66 |

| Iron sulphide | 2.64 |

| Magnesia | Trace |

| Manganese oxide | 0.40 |

| Gold | 1.68 oz. per ton. |

| Silver | 0.20 oz. per ton. |

| Sulphur | 0.96 per cent. |

The value of the gold contained in the ores treated varies from 18.00 dols. to 50.00 dols. per ton, although higher grades are sometimes purchased. The mixture in the beds will average in the neighbourhood of 30.00 dols. per ton. It is found that as the grade improves the percentage of extract ion improves also ; for while with 18.00 dols. ores the percentage of gold recovered may barely reach 92 per cent., the percentage on 50.00 dols. ores reach 96 per cent., the figures being based on gold settled for as per assay, against gold actually recovered in the bullion.

In connection with the above plants the following details may be of interest. The form of crushing roll used in all three mills is shown in longitudinal and vertical section on page 4 ante. The machine is constructed with a self-contained frame, the pillow-blocks carrying the lower roll being cast into each side-piece. The roll shafts are of wrought, iron, and run on babbitt-lined bearings. The principal feature of the machine is in placing the rolls one above the other as shown, the top roll being mounted in a sliding cast-iron yoke or crosshead, which is free to slide between vertical machined guides cast into the main frame. The direction of strain between the rolls due to the weight of the top roll and connections, being at an angle of 45 deg. to the direction in which the. top roll is free to rise, gives a very effective pressure at the point of contact for crushing. The top roll being securely guided, retaining the shafts parallel to each other, helps to prevent unequal wear of the crushing surfaces. The weight of the top roll is supplemented where necessary, by spring pressure, the springs being placed on each side of the yoke- piece with tension-rods run through the base of the machine. The crushing shells are made of high-carbon forged steel machined all over, and fitted to the cast-iron centres with taper, and are secured to place by through bolts. The ore is fed to the machine directly over the lower roll, the bottom of the hopper being made removable for cleaning out.

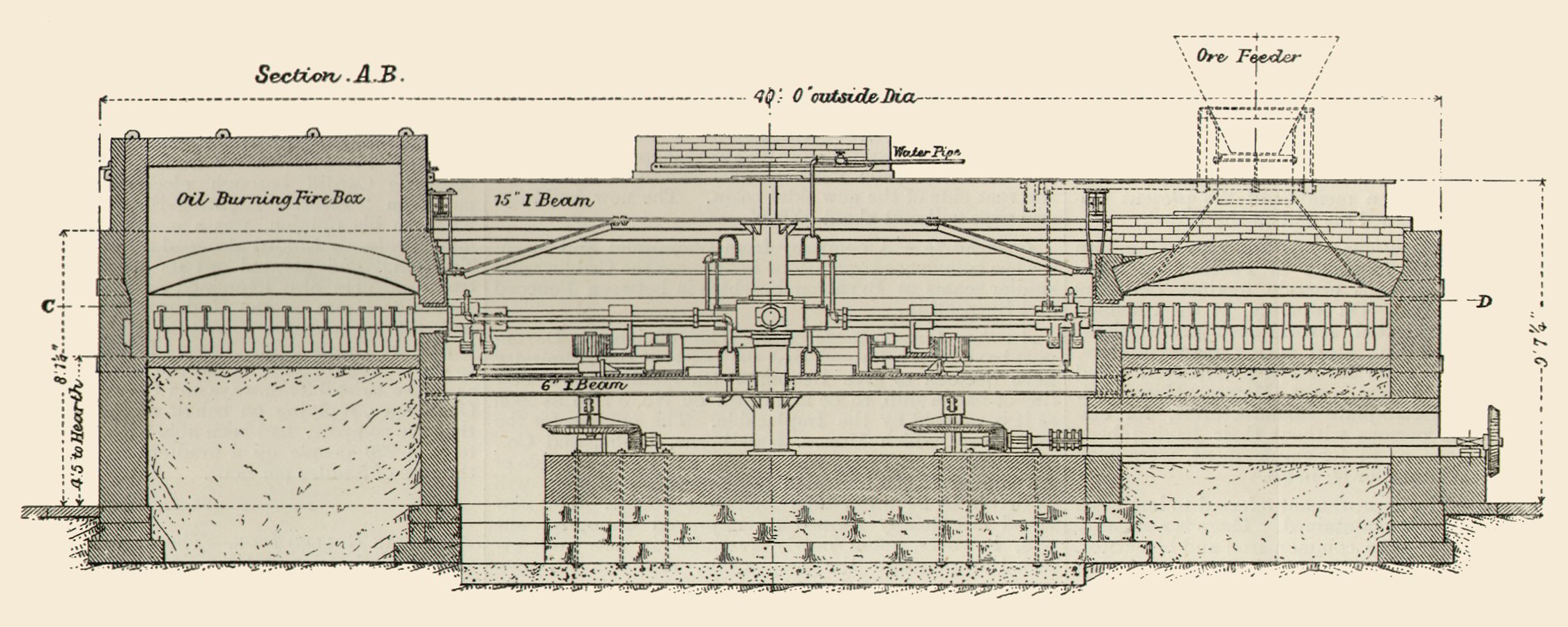

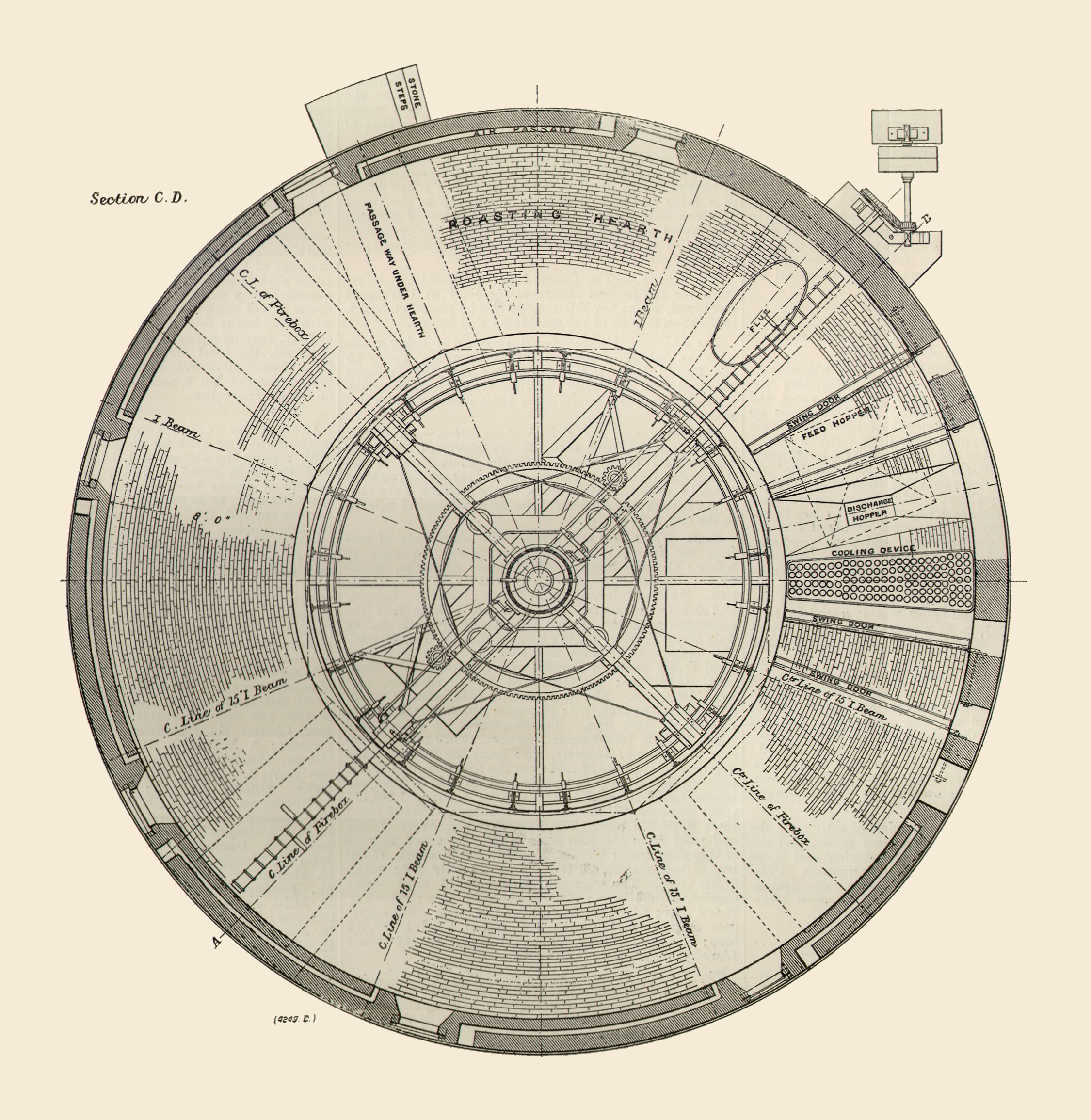

The Pearce roasting furnace, as installed in the El Paso Reduction Company's works, is shown in vertical and horizontal section on page 236.# As will be observed, this furnace is circular in form, 40feet outside diameter, the width of the roasting hearth being 8 feet The driving mechanism is placed in the centre of the furnace, and consists of a main central driving gear operated by means of bevel gears and a shaft running through under the hearth to the outside of the furnace. This shaft is driven by 45 deg. gears. The main driving gear in the centre chamber is fitted with cast-iron brackets carrying 6-inch wrought-iron pipe arms forming a central revolving spider or wheel. This is supported on a circular track formed of 60-lb. rail. The central spider is carried on eight 12-inch cast-steel wheels, which run on a circular track, and is maintained central with the furnace by means of four 12-inch rollers running in contact with the inside of the main driving gear. The rabbles, or stirring arms, which turn the ore on the hearth, are made of 6-inch extra strong wrought-iron pipe, projecting over the hearth through the circular slot in the inside wall. These arms have rabble blades bolted to them, the blades on one arm being made to follow opposite the spaces between the blades on the arm in advance of it. The furnace is fitted with two or four arms, as the nature of the work may require. The arms make a complete revolution in about 85 seconds, and are kept cool by means of water circulating in the pipes, the water connection being clearly shown on the plans.

By examining the drawings it will be seen that to maintain a continuous open slot for the passage of the arms, the inside support for the brick arch over the hearth must be carried from above. This is done by means of eight 15-inch steel I-beams resting on the fixed central column at one end, and bearing plates on the outside wall of the furnace at the other, the skew-back being carried on cast-iron Z-shape segments, forming a complete circle hung by stirrups to the 8-inch I-beams, supported by the 15-inch radial beams above referred to. The circular slot is closed to prevent the influx of cold air, by means of No. 16 sheet-iron shields, held in place by weighted levers. The furnace is fired from three points in the circle. The fireboxes (built directly over the hearth), are 6 feet wide, 8 feet long by 2 feet 3 inches high, with openings 10 inches square at one side, through which the oil is injected. The opposite side of the firebox is fitted with a loose target of firebrick against which the oil spray breaks. The oil is sprayed into the firebox by steam which is supplied to the burner at about 90 lb. pressure.

In roasting 50 tons per day the furnace consumes about 20 barrels of residuum, costing about 50 cents per barrel. The raw ore is fed to the furnace by an automatic feeder, from which it falls directly on to the hearth, and being carried around a short distance with each pass of the rabbles, it is finally delivered after an exposure of about 4,5 hours, to the tubular cooling device, and from that to the conveyor, by which it is delivered into the elevators in the chlorination room. The labour required to operate this furnace is one man on a shift to each furnace to regulate the apparatus and oversee its working. The cost of roasting is about 35 cents per ton of ore at Florence. About 5 horse-power is required to operate each furnace.

Since the above article was written, it has been thought advisable at the El Paso Reduction Company's Mill, Florence, to discontinue the use of the automatic cooling and conveying mechanism between the roasting furnaces and the chlorination building, due to the difficulty found in keeping the pipes and connections to the cooling device open.

The water available is extremely bad, and a very heavy deposit of scale was continually forming in all the pipes and connections, involving serious delays and heavy costs for repairs. The ore is now taken from the furnaces in barrows and distributed on a cooling floor in the usual way.

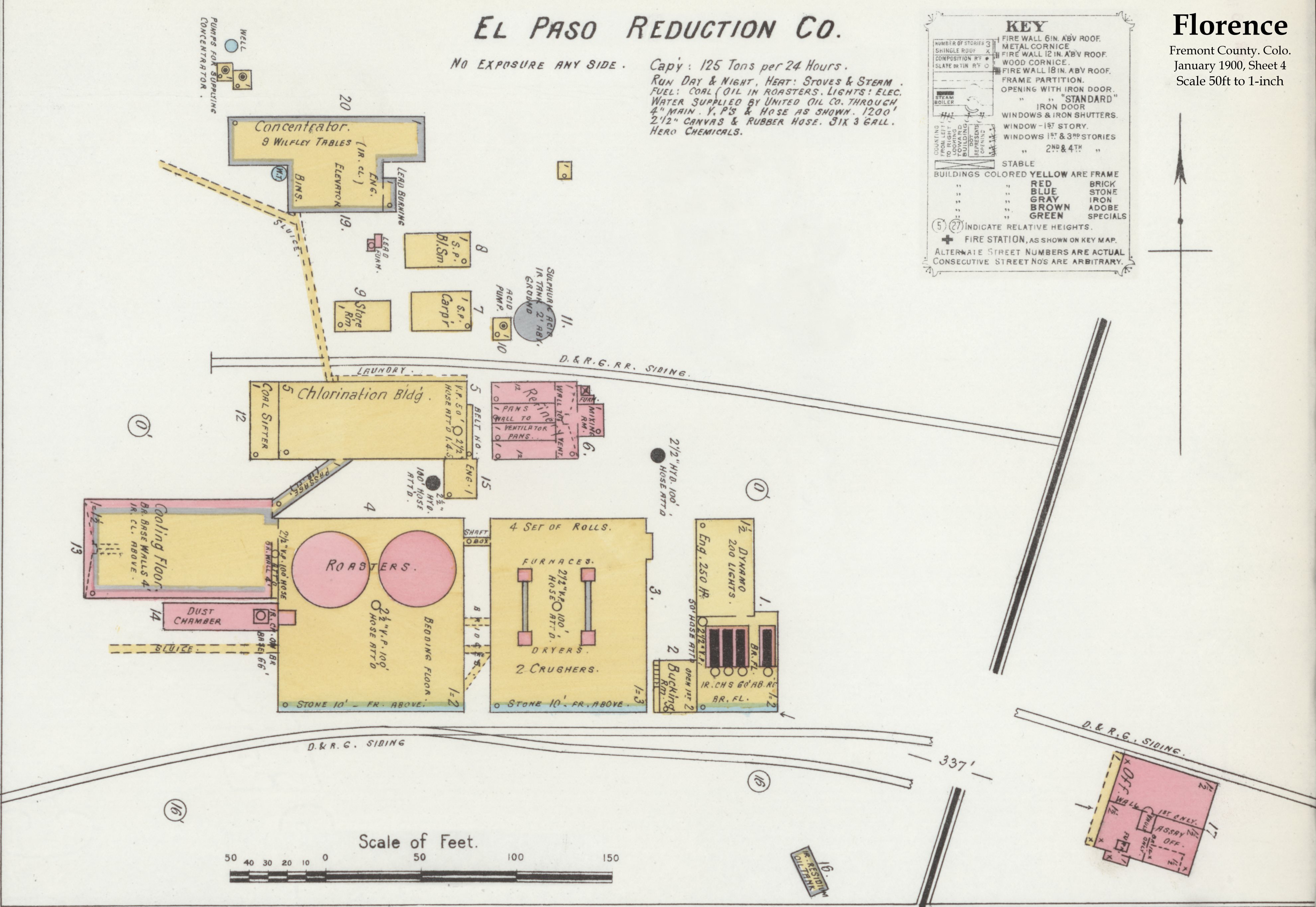

This 1900 Sanborn Fire Insurance Map for the El Paso Reduction Works of the El Paso Reduction Company is the only one that exist with this type of details! The Mill was probably built in 1898, while Sanborn has an 1890 edition making that too early, and it don't appear in the 1906 edition of the Sanborn, possible already burned down.

This 1900 Sanborn Fire Insurance Map for the El Paso Reduction Works of the El Paso Reduction Company is the only one that exist with this type of details! The Mill was probably built in 1898, while Sanborn has an 1890 edition making that too early, and it don't appear in the 1906 edition of the Sanborn, possible already burned down.

I reposition and added in some info-pieces from other places on the larger sheets this is cropped out of, also, I turned it so north is up and straighten the map so it aligns along the south walls, but other than that, the map is as it was made. The Office structure at lower right is not 'distance correct shown' but the distance is given as a number as this was a Sanborn feature on their own map.

I reposition and added in some info-pieces from other places on the larger sheets this is cropped out of, also, I turned it so north is up and straighten the map so it aligns along the south walls, but other than that, the map is as it was made. The Office structure at lower right is not 'distance correct shown' but the distance is given as a number as this was a Sanborn feature on their own map.