-> HathiTrust Digital Library Site; Link to First page of article.

Image quality varies as I do no have the original source paper, but had some images already in my collection.

Once more is the scientist vindicated in practice, and we now have a furnace for boiler practice, ore roasting, and smelting purposes, which has been patented by J. Elmer Parkison, and improved under what is known as the Manhire-Porter patents, which is consuming the volatile portion of all combustible matter and thereby getting the highest efficiency out of the fuel consumed.

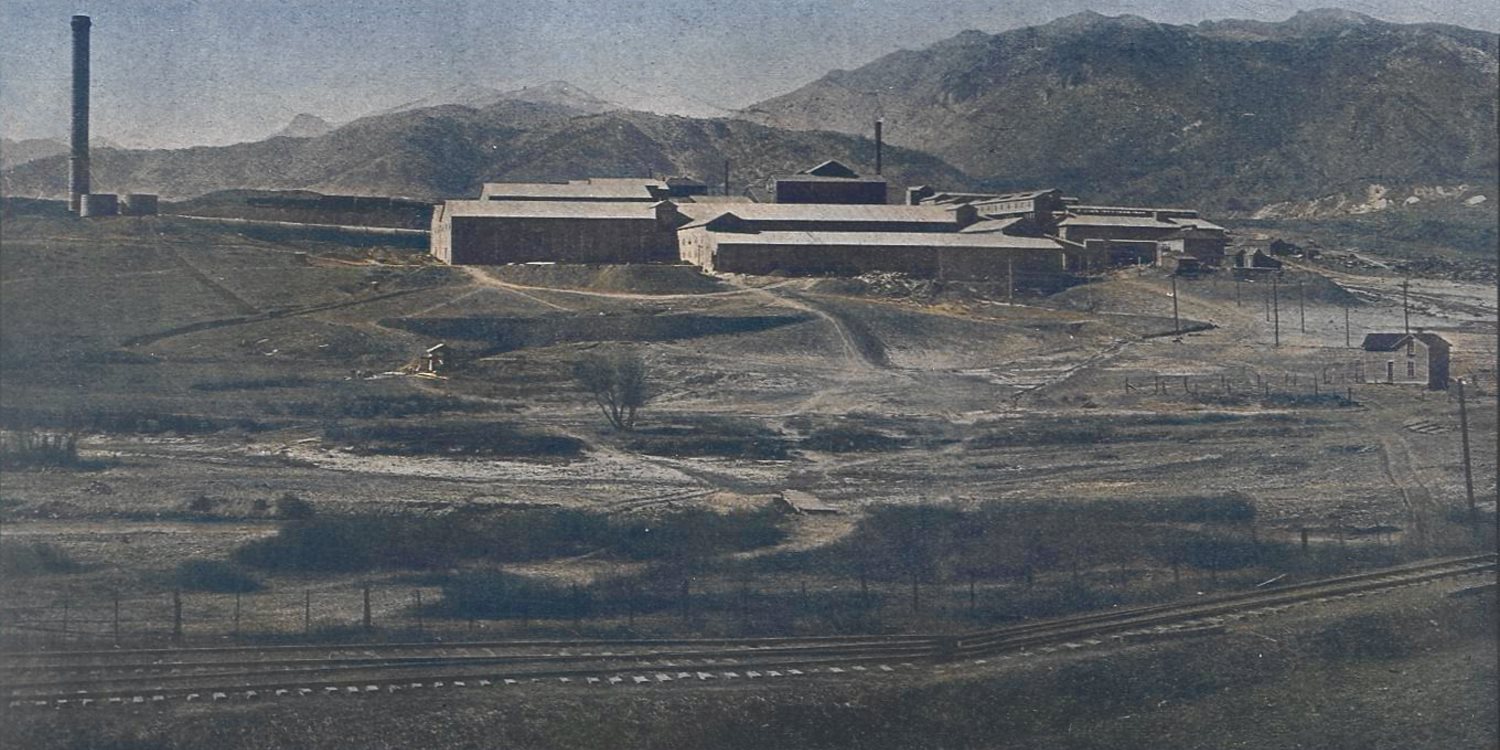

Large Reduction Plant of The Golden Cycle Mining Company, Colorado City.

Equipped With 27 Parkison Furnaces,

Attached to Edwards Roasters and Three Under Boilers.

We believe that our readers will be interested in a little history of this apparatus. Like many other things of its kind coming as it did, into being from the sheer force of necessity.

In the early days of the roasting of Cripple Creek ores at Colorado City, the mills found it impossible to procure sufficient oil, the only fuel that had been used up to that time for this purpose, therefore Mr. Parkison and his associates found themselves in a position where they must burn coal.

They experimented with bituminous coal which was shipped to them from the southern part of Colorado, at an expense of $3.00 per ton. They had just succeeded in using this coal in their furnaces when the great bituminous coal strike of 1903 closed down the bituminous coal mines, and left them again with nothing but their pluck and ingenuity to draw on and as in most cases this proved to be sufficient.

They, therefore, tackled the lignite coal in the vicinity of Colorado Springs, and again the fight was renewed. One of the party sought the aid of the scientist and made a trip to the Colorado College in an attempt to draw from the professor some answer to the problem. He was informed that lignite coal was better in reality, than common use and experience had been able to demonstrate it to be in actual practice.

When inquiry was made why this was so, the scientist stated that much of the heat value was carried in what was known as the volatile portion of the coal contents. This portion of the fuel, he advised, was what was known as hydro-carbons, and left the coal in a volatile state immediately following the discharge of the moisture and at a comparatively low temperature, but as it required an exceedingly high temperature to burn it, higher than was ordinarily obtained in the average fire-box and roaster, it consequently escaped with the dry gases and either deposited itself as soot in the combustion chamber and flues, or went off in the shape of gas from the top of the stack.

This loss resulted (in boiler practice) in pulling down the efficiency of this practice to about 50% to 54%, but the scientist said that could this gas be consumed, it would then be converted into heat, and if properly applied would result in a very great increase in the efficiency of this fuel.

This is where science was right, and Mr. Parkison and his associates immediately proceeded on this theory and after many hard-trials succeeded in evolving what has since become the successful appliance known as the Parkison Patent Lignite Furnace, and while this name is used in the original title, the word Lignite is no longer sufficient for the reason that one improvement after another, one success after another, has brought about the conquering of practically all fuels that are on the market, even including oil and natural gas, as all fuel either lignitic or otherwise, contains a certain portion of its heat value in the form of hydro-carbon, and was subject in the old method and practice to a constant loss.

Mr. Parkison from this early beginning branched out and established an office and factory in Denver, where he incorporated a company known as the Western Furnace Company.

In 1908 Mr. Parkison, on account of a break-down in health, was compelled to turn the active management over to his associates, and Mr. Samuel G. Porter succeeded to the presidency of the company; Joseph W. Phillips assuming the Vice Presidency, and Mr. H. G. Cunningham becoming Secretary and Treasurer. Under this new management the company has forged to the front, and procured patents throughout the most of Europe, Mexico, Canada and Australia, and are now negotiating for South American states.

_gold-coin-of-granite-gm-co-use-parkison-furnace-colored1before_i-03051.jpg)

Before Installing Parkison Furnace.

_gold-coin-of-granite-gm-co-use-parkison-furnace-colored2after_i-03051.jpg)

After Installing Parkison Furnace.

Mr. Parkison took charge of the northwestern country with headquarters at Seattle.

The company proceeded to demonstrate the merits of the furnace on other than Colorado coals and after demonstrating its use in Missouri, Texas, Arizona, New Mexico, Montana and Washington, and making further laboratory and working tests with coals from different localities, found it necessary in order to push the business in the several territories mentioned, to establish an additional company which should act as a holding company for the several subsidiary companies that it was planned to establish.

In the spring of 1911 the officers of the Western Furnace Company incorporated what is known as the International Engineering Corporation, with ample capital to carry on the development and exploitation of this work throughout the world.

The Western Furnace Company, however, will continue to be the main operating and constructing company for the middle west, as the plan as proposed by the managers of this company is to proceed as fast as practical and bring their subsidiary companies into operation dividing up the territory as seems most expedient and convenient, which among other plans will be to open offices in Birmingham, Alabama; Chicago, Ill.; Kansas City, Mo., and probably San Francisco.

They have just recently placed their agency for the Australian colonies with the Edwards Corporation, who are the leading operators in the reduction of ores throughout the field, and are known in this country as the manufacturers of the popular and successful roaster, bearing Mr. Edwards' name.

The Australian agency was sought and secured by Mr. Edwards when he learned that the Parkison Furnace was successfully used by the Golden Cycle Company under his ore roasters.

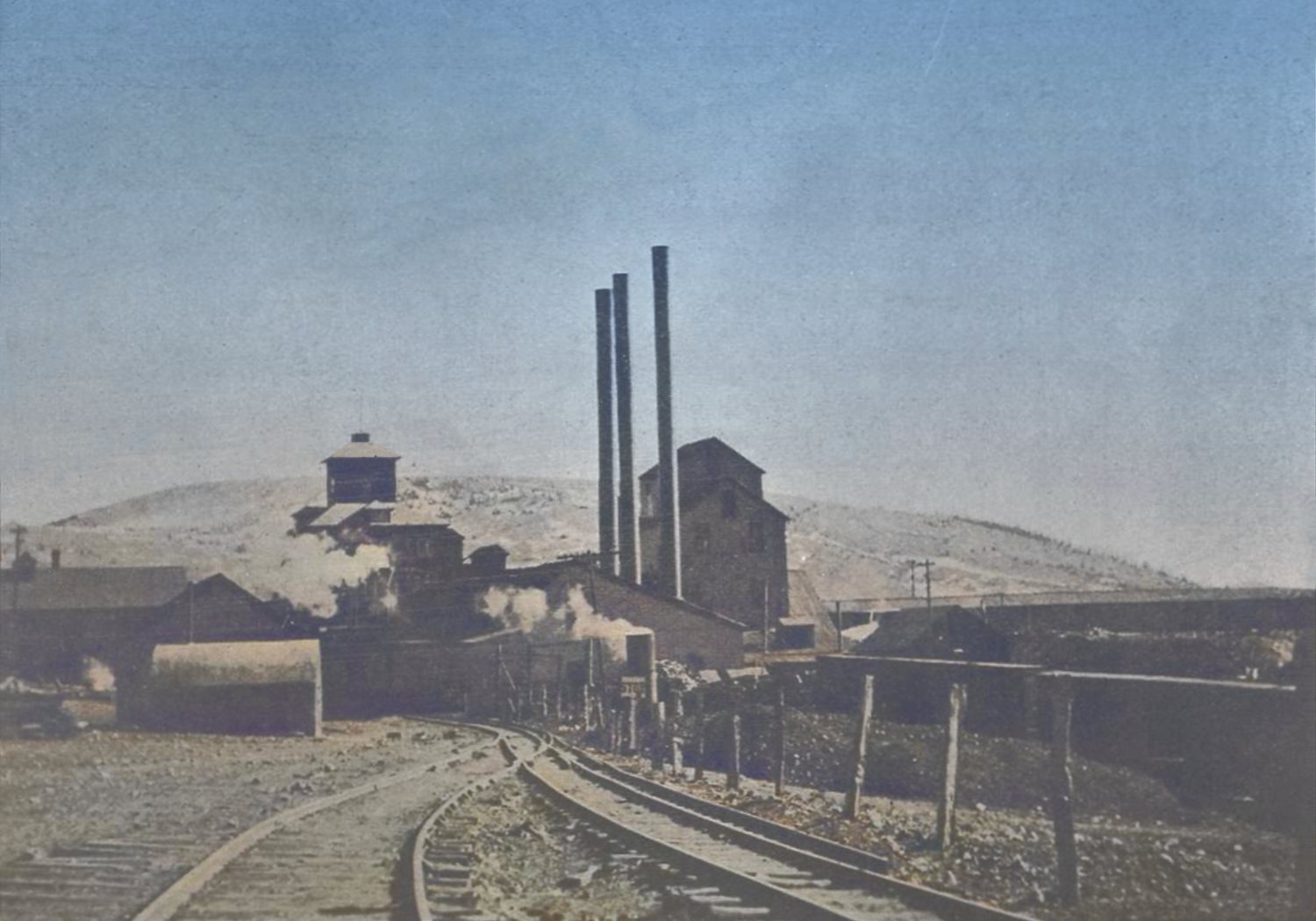

The Western Furnace Company first placed their appliance on seven of the Edwards roasters. The Cycle Company then had the misfortune to have a fire that practically wiped the plant out. Mr. Milliken, with his usual force and energy, immediately rebuilt the plant, adding the eighth roaster, which he equipped with Parkison Furnace, and within the last month this company has found it necessary to add the ninth roaster, which they also equipped with Parkison Furnaces.

They also have their boilers at the mill equipped with these furnaces, as well as the five boilers at the mine plant at Cripple Creek. At this Cripple Creek plant, the general manager, Mr. McGarry, says the fuel economy effected by the Parkison Furnace amounts to $1,300.00 per month.

While mentioning Cripple Creek, we might as well refer to some of the letters from other patrons of this company.

Mr. Campbell, general manager of the Vindicator Gold mine says, under date of May 13, 1907: "The economy effected is practically $1,000.00 per month."

Mr. Sigel, in a letter dated January 21. 1906, says that the economy effected since installation has amounted to almost 50 per cent.

Mr. R. Roelofs of the Cresson Consolidated Gold Mining Co. says that the economy secured at their plant is something over 30 per cent.

Mr. Allen Burris, president of the El Paso Consolidated mine, says under date of November 18, 1911, their fuel bills have been cut from $1,600.00 per month to $1,000.00 per month.

We feel that letters from other sources and localities would perhaps be interesting, and therefore we quote from a few of them as follows:

President John J. Sherwin of the United Hydro Electric Co., Georgetown, says in part: "I am satisfied that the Furnace would make a saving in five months equal to the total cost of the installation. As this is much better than you promised, and more than we expected, we are highly gratified with the results."

Mr. J. C. Fleschhutz, president of the Pewabic Cons. Mining Co., of Blackhawk, Colo., says in part, under date of April 22, 1911: "In fact, since the installation of the Furnace we have never had cause for a single penny's expense in repairs to furnace or boilers, and we can truthfully say we have saved over 35 per cent over cost of our former coal bills."

Irving T. Snyder, general manager of the Western Alkali Manufacturing Co., of Green River, Wyo., says, in letter dated September 27, 1911, that his plant in which the Western Furnace Co. had installed a new Heine Boiler and Parkison Furnace, at the same time overhauling the plant and putting it in shape generally, shows greater efficiency. His letter in part follows:

"Not having any definite data in hand we nevertheless have discovered that under the improved conditions since the installation of Heine Boiler, and general repair work under your supervision, we have increased our capacity three to fourfold, and are operating with a saving in coal of from 20 to 25 per cent. Herewith you will find a statement of the boiler test later run on this plant. You will notice that there was a very heavy overload carried; notwithstanding this the efficiency was high."

The Company have a vast number of letters, but we will not attempt to quote from all of them.

Among these we notice such prominent names as the United Verde Copper Co., Jerome, Ariz., one of the properties of the great Copper King, Senator Clark. We understand that the Senator has the same furnace in use at his plant at Butte, Mont There is also a letter from the general manager of the Crescent mill of Denver.

Another from W. E. Renshaw of the Gem Leasing Co., and another significant letter from the mayor of Georgetown, thanking the Western Furnace Co. in behalf of the city for the abatement of the smoke nuisance, which formerly smothered this little town, which is in a narrow mountain gorge, with the dense body of smoke discharged from the stacks.

This brings us to another phase of the benefits of this Furnace, namely: its smokeless operation.

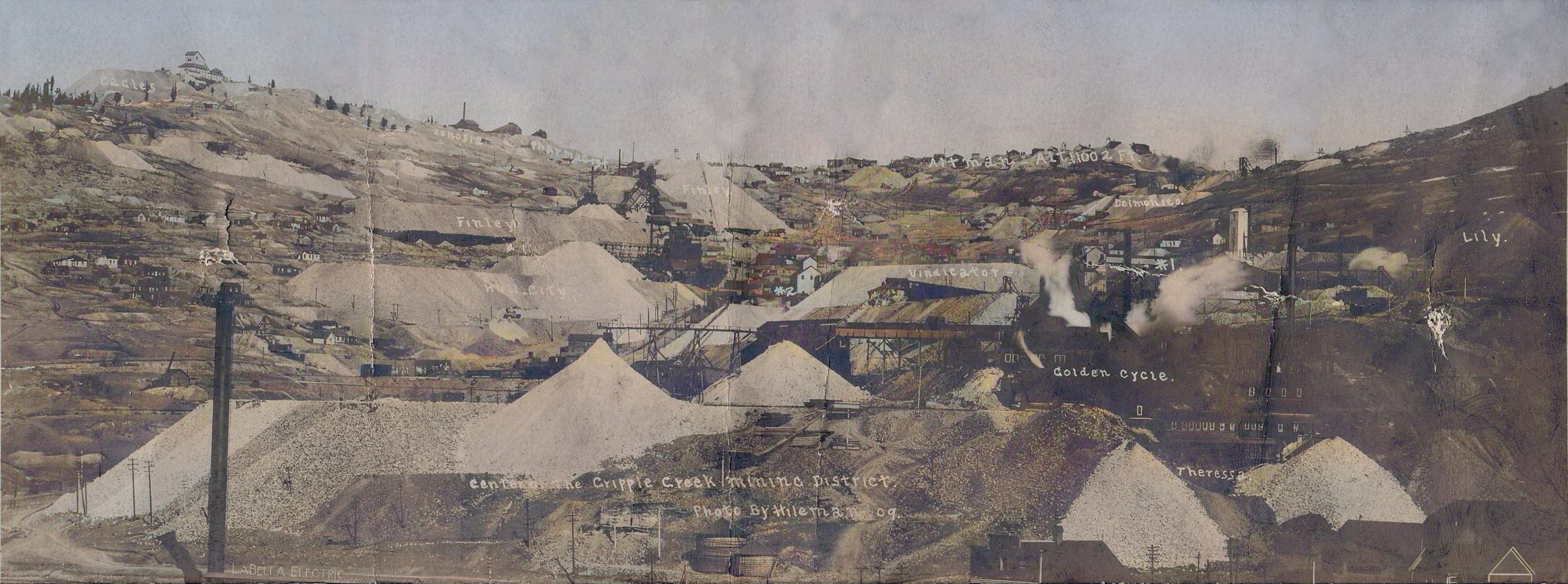

East Slope of Bull Hill, Cripple Creek District, Showing Absence of Smoke Where Parkison Furnaces Are Used.

As already stated, this is accounted for by the complete combustion, thus leaving nothing to discharge from the stack but dry gas, all the product of combustion known by the symbol CO2, together with the nitrogen and a small quantity of excess oxygen.

Some of the cuts that will appear with this article will show the condition of the stacks and a close perusal of the boiler tests, which include stack analysis, will give the scientific reasons why these stacks are clean.

We feel that perhaps our readers will be interested in a description of the means by which these economic results are procured. The main point in combustion and the point emphasized in this operation is the pre-heating of the air which is to aid and complete combustion.

The proper mingling of this air at the right temperature is accomplished in two ways. First the fuel bed rests upon a series of grate bars which are water cooled, and drop well to the floor line, leaving ample room between the fuel bed and the shell of the boiler. This fuel bed consists of a layer of cinders or ashes of some two to four inches thick; upon this filter bed rests the green coal and fire with a varying thickness of from 12 to 20 inches in different stages of combustion.

Air to burn the fixed carbon and liberate the gases is introduced under the fire in a sealed ash pit, and is what is called primary air. This is introduced under slight pressure in order to drive it up through the fuel bed, but not with sufficient pressure to act as a forced draft, there being a negative pressure over the fire. As this primary air is not sufficient to complete combustion, secondary air as before mentioned is brought in through ducts in the walls and discharged through orifices under an arch which is thrown across the fire.

This arch has a slight retaining effect upon the flame, and sets up a reverberatory action, thoroughly mixing the pre-heated air with the gases from the fuel bed. These gases are then released to the combustion chamber, where they are allowed to expand, and the combustion is completed.

All the air, both primary and secondary, are under perfect control, thereby enabling the operator to reduce his quantity or increase it as the tests of his flue gases would indicate the necessity.

In the roasting of ore at the Golden Cycle plant at Colorado City the operators have illustrated their ability to control this flame so perfectly that they make it reach 40, 50 or even 60 feet, and then immediately pull it down to within 10 feet of the bridge wall at their will.

Another point that should be mentioned in connection with the Parkison Furnace is the extraordinary clean ashes, or, in other words, the small amount of combustible matter which remains in the ashes from these furnaces. The deep fuel bed enables the fires to be carried much longer without cleaning, and when cleaned the shaking grate permits the ashes to be drawn from the bottom of the fuel bed.

In the burning of lignite coal it is a common thing for a boiler running under full load to go 24 to 36 hours, and even 48 hours, without as much as even being shaken.

We should also mention there is a small quantity of exhaust steam discharged into pit along with the primary air. This prevents high temperature in the bottom of the fuel bed, thereby wholly obviating the troublesome element known as the clinker.

The Western Furnace Co. predicts the application of their principle of their furnace to each and every kind of combustion.

Senator Clark, in his operations at Jerome, has proven that it will burn oil with marked increase in efficiency. Mr. Roelofs of the Cresson mine at Cripple Creek, has proven the burning of wood and sawdust. The Darbyshire Harvie Iron and Machine Co. at El Paso, Texas, has proven that it will burn refuse from the city, street sweepings and all kinds of offal.

The Company has also experimented with the low-grade, high-moisture lignites of North Dakota, and it seems reasonable to presume that anything containing hydrocarbon or combustible matter can be used in these Furnaces, and that the application will extend to not only the roasting of ore, but to the burning of clay products and the calcining of cement and lime rock.

The Company has recently closed a contract for the construction of their Furnace for use in the Joplin zinc fields, and is now installing several of their Furnaces with the Pittsburg Zinc Co. of Pittsburg, Kans. It also expects to apply this apparatus to locomotives and ships at sea.

One can hardly realize what the future is for a Furnace that shows from 25 to 40 per cent economy, as this Furnace has testimony to show. For instance, let us take the Empire of Germany, where they are so jealous of their coking coal for their steel industry, which is their life trade, that they have ceased to burn this class of coal upon locomotives and other steam plants, and are substituting for this valuable fuel the low-grade brown lignites of the upper Rhine, which are so high in moisture (running from 38 to 52 per cent) that in order to burn them they are putting them to a severe cost of preparation.

This is best expressed by quoting from bulletin No. 14, Bureau of Mines, entitled "Briquetting Tests of Lignite at Pittsburg," by Charles L. Wright, Government Printing Works, 1911.

This article is indeed interesting, and we glean from the statistics some very important points. Among other facts we find that they compare this coal to our North Dakota, Montana and Texas lignites. But, to come down to the first subject, namely, the use and application of this coal to the German Empire, we find that in the year 1910 they briquetted 21,575,000 tons of this lignite. This manufacturing cost is necessary in order to make it possible to consume this fuel to any advantage, but the cost is something terrific.

Quoting from page 45 of this report we find as follows, under the heading:

Cost of Briquetting.

"The cost of briquetting run-mine lignite with the German plant would be from $1.35 to $1.75 per ton, according to the location of the plant."

It is the belief of the officials of the Western Furnace Co. that they can take this coal as it comes from the ground, and after perhaps merely sun-drying it in order to drive off at a very low cost a considerable percentage of the moisture, they could then burn it and procure as high a boiler efficiency, or higher, than the Germans are now procuring from their manufactured briquettes.

The reason for this is based upon the fact that they have burned a coal which is almost identical which comes from Williston, N. D., and we have tabulated here a comparative boiler test made by them at their Denver plant on this coal and contrasted with the work of the government at St. Louis, burning the same coal but under different practice than used with the furnace. We believe a glance at this comparison will prove their theory.

As time advances the world begins to realize the necessity of greater economy and efficiency in the use of our great natural resources. This is becoming a painful subject, particularly in the over-populated narrow limits of many of the countries of Europe, and even the great and extravagant United States has begun to realize this necessity, and we understand this Company is prepared to offer its patrons a showing of 20 per cent over their ordinary flat-grate practice, and it would seem from their letters that this more frequently reaches 30 per cent.

They advise us that they intend to invade the New England field, where the great cotton, leather and other manufacturing concerns are beginning to suffer for the need of economy and power, as they have long since utilized all their water and all wood fuel is gone, they must draw upon the Virginias and Pennsylvania for fuel, whereas they have in Maine and Nova Scotia vast deposits of low-grade peat and semi-lignite fuel. This is also true of California, which is not classed as a coal state at all, and the states of Michigan, Wisconsin, Iowa, North and South Dakota, Montana and Texas.

Then again, one's mind comes back to what it means to ships at sea, could their fuel cost be reduced 20 to 30 per cent. Not only would it reduce the cost of operation, but for every ton of coal that was displaced they would replace it with a ton of cargo. Further, what would it mean to the navy if a squadron of modern battleships using from 25,000 to 45,000 h. p. per unit could come up within 15 miles of an enemy and never betray their presence?

The following recent tests are good examples of the efficiency of the Parkison furnace:

Results of the trials at the Western Alkali Manufacturing Company plant at Green River, Wyo., to determine evaporation, by Weber, Manhire and I. T. Snyder of Western Alkali company:

| Parkison Furnace. | |||

| Date of trial | 10-27-11 | ||

| Duration of trial, hours | 4 | ||

| Dimensions and Proportions— | |||

| Type of boiler, Heine 102-160-18 | Heine | ||

| Size of boiler—H. P. | 282 | ||

| No. of tubes | 160 | ||

| Size of tubes, inches, diameter | 3.5 | ||

| Grate surface, 57.5"x84" area, sq. ft. 33.5x2 | 67 | ||

| Water heating surface, in sq. ft. by builders | 2,820 | ||

| Ratio of water-heating surface to grate surface | 1,642.1 | ||

| Average Pressures— | |||

| Barometer, inches mercury, Atmos. Pressure 12.5 | 24.5 | ||

| Steam pressure in boiler, by gauge, lbs. | 108 | ||

| Absolute steam pressure, lbs. | 120.5 | ||

| Force of draught in inches of water in chimney | .61 | ||

| Average Temperatures— | |||

| Of external air, deg. F. | 47 | ||

| Of fire-room, deg. F. | 74 | ||

| Of steam, deg. F. | 348.5 | ||

| Of escaping gases, deg. F. | 740 | ||

| Of feed-water, deg. F. | 121 | ||

| Fuel— | |||

| Coal, Rock Springs district | |||

| Size and condition, slack, clean | |||

| Total amount of coal consumed, lbs. | 6,530 | ||

| Moisture in coal, per cent | 7.35 | ||

| Dry coal consumed, lbs. | 6,050 | ||

| Dry coal consumed per hour, lbs. | 1,512 | ||

| Proximate analysis: | Moisture, % | 7.35 | |

| Volatile Matter, % | 37.40 | ||

| Fixed Carbon, % | 49.95 | ||

| Ash, % | 5.30 | ||

| B. T. U. per lb. dry coal by Parr calorimeter | 12,608 | ||

| Analysis of Ash and Refuse— | |||

| Carbon, % | 5.76 | ||

| Earthy matter, % | 94.24 | ||

| Results of Calorimetric Tests— | |||

| Percentage of moisture in steam, no correction made | |||

| Flue Gas Analysis— | |||

| Carbon dioxide (CO2) % | 10.6 | ||

| Carbonic oxide (CO) % | .0 | ||

| Oxygen (O) % | 8.7 | ||

| Nitrogen by difference (N) % | 80.7 | ||

| Air supplied per lb. carbon, lbs. | 28.1 | ||

| Theoretical air required per lb. carbon, lbs. | 11.3 | ||

| Water— | |||

| Total weight of water fed to boiler, lbs., 48,345 at 65 deg., corrected to 41 deg. as weighed | 48,407 | ||

| Factor of evaporation | 1.35 | ||

| Equivalent water fed to boiler from and at 212° F. | 54,941 | ||

| Equivalent water evaporated into dry steam from and at 212° F. per hour | 137.35 | ||

| Economic Results— | |||

| Results Deducting Fan Engine, Etc. | |||

| Water evaporated per lb. coal as fired | 7.413 | 7.26 | |

| Equivalent water evaporated from and at 212° F. per lb. coal as fired | 8.413 | 8.11 | |

| Water actually evaporated per lb. of dry coal from actual pressure and temp., lbs. | 8 | 7.83 | |

| Equivalent water evaporated from and at 212° F. per lb. dry coal | 9.08 | 8.88 | |

| Horse Power— | |||

| Horse power developed (34½ lbs. of water evaporated into dry steam from and at 212° F. per hour) | 398 | 390 | |

| Horse power, builders' rating at 10 sq. ft. heating surface per horse power | 282 | ||

| Per cent of builders' rated horse power developed | 141 | 138.4 | |

| Horse power developed per sq. ft. of grate surface | 5.94 | 5.82 | |

| Efficiencies— | |||

| British thermal units in coal (calorimeter) B. T. U. per lb. dry coal | 12,608 | ||

| British thermal units absorbed in water, B. T. U. per lb. dry coal | 8,768 | 8,575 | |

| Efficiency of boiler and furnace | 69.5% | 68.1% | |

| Note.— | Live steam used by fan engines | 125 lbs. per hr. | |

| Live steam used in ash pit | 125 lbs. per hr. | ||

| ———————————— | |||

| Total | 250 lbs. per hr. | ||

Equals 1,000" in 4 hours or 1.82% of total evaporation.

Computed by ROBT. J. HILL, Engineer.

Checked by HERMAN R. WEBER, Chief Engineer.

UNITED STATES TEST.

Column No. 1 shows the results obtained by the U. S. G. S. Testing Plant at St. Louis; Test No. 33 and copied from part 2, page 771, report of the same.

Column No. 2 shows the results obtained at the Experimental Plant of the Western Furnace Co., Denver, Colo., using the Parkison Lignite Furnace.

| No. 1. Standard Grates. |

No. 2. Parkison Furnace. |

||

|---|---|---|---|

| Type of boiler | Heine, W. T. Return Tube | ||

| Size of boiler—H. P. | 210 | 80 | |

| Fuel— | |||

| Coal, Lignite from Williston, North Dakota; Miller mine in both cases | |||

| Proximate analysis: | Moisture, % | 35.84 | 38 |

| Volatile Matter, % | 28.13 | 25.95 | |

| Fixed Carbon, % | 25.40 | 29.8 | |

| Ash, % | 10.63 | 6.25 | |

| B. T. U. per lb. dry coal by Parr calorimeter | 10,192 | 10,904 | |

| Analysis of Ash and Refuse— | |||

| Carbon, % | 41.87 | ||

| Flue Gas Analysis— | |||

| Carbon dioxide (CO2), % | 4.74 | 13.53 | |

| Carbonic oxide (CO), % | .00 | .00 | |

| Oxygen (O) | 15.96 | 6.08 | |

| Nitrogen by difference (N), % | 79.30 | 89.30 | |

| Economic Results— | |||

| Equivalent water evaporated from and at 212° F. per lb. dry coal | 5.40 | 8.96 | |

| Horse Power— | |||

| Horse power developed (34½ lbs. of water evaporated into dry steam from and at 212° F. per hour) | 108.9 | 80.6 | |

| Horse power, builders' rating at 10 sq. ft. heating surface per horse power | 210 | 71.75 | |

| Per cent of builders' rated horse power developed | 51.9 | 113 | |

| Efficiencies— | |||

| British thermal units in coal (calorimeter) B. T. U. per lb. dry coal | 10,192 | 10,904 | |

| British thermal units absorbed in water, B. T. U. per lb. dry coal | 8,632 | ||

| Efficiency of furnace and boiler | 60.13 | 79.4 | |

| Gain in efficiency of Parkison Furnaces over Standard Grates | 58.39% | ||

_parkison-furnace-applied-to-water-tube-boiler.png)

_parkison-furnace-attached-to-return-tube-boiler.png)