-> My Collection, Also on

-> the Internet Archive Site; Link to article.

New Year Edition 1903

(page 76)

Source had two pics, I added the drawing image + extra pic from my collection

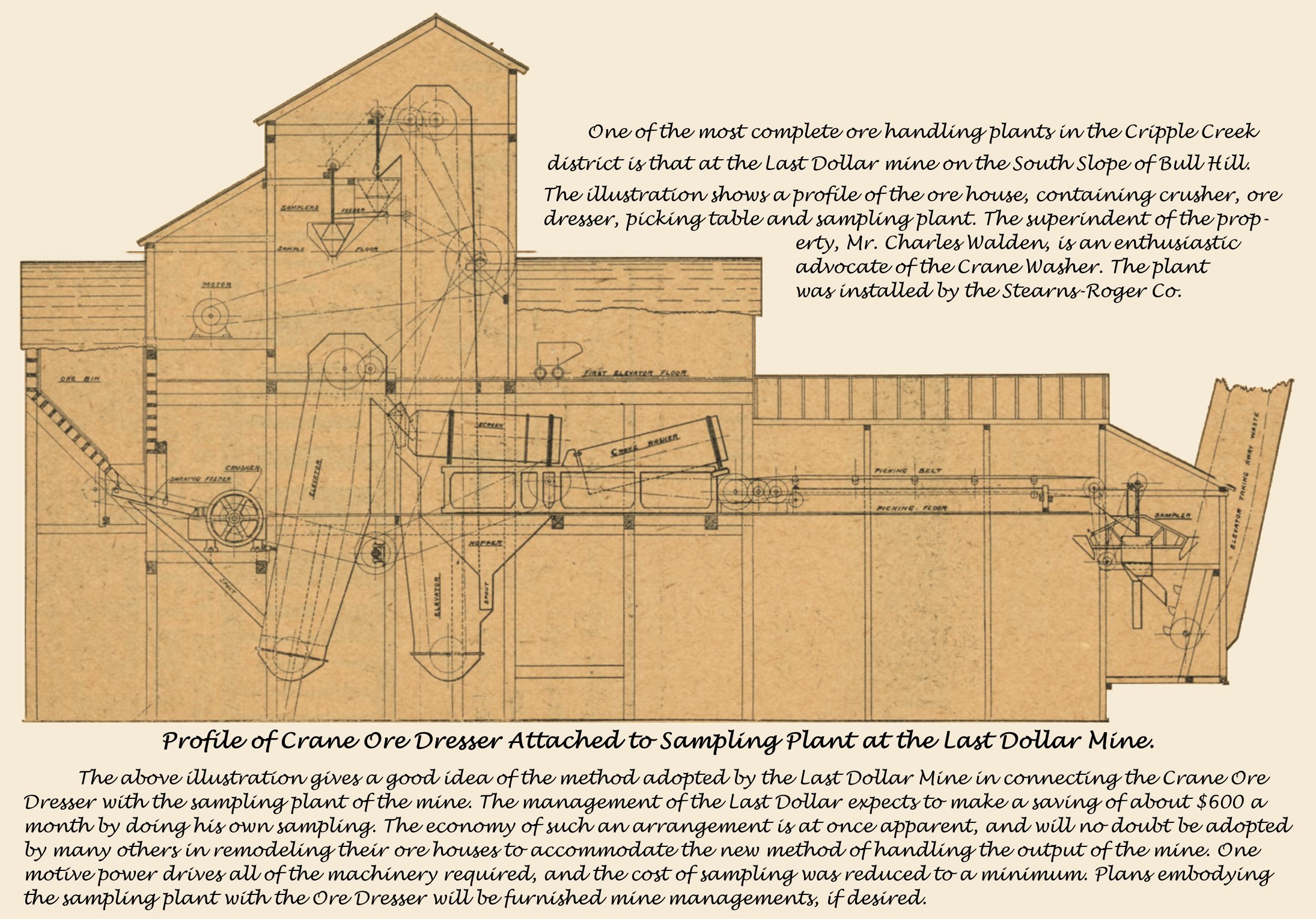

The claims of Crane's Automatic Ore Dresser and Picking Table are not visionary, but are founded on the actual experience of the inventor and others operating several machines in the Cripple Creek district, the ores of this district being the hardest to handle of any known in the world.

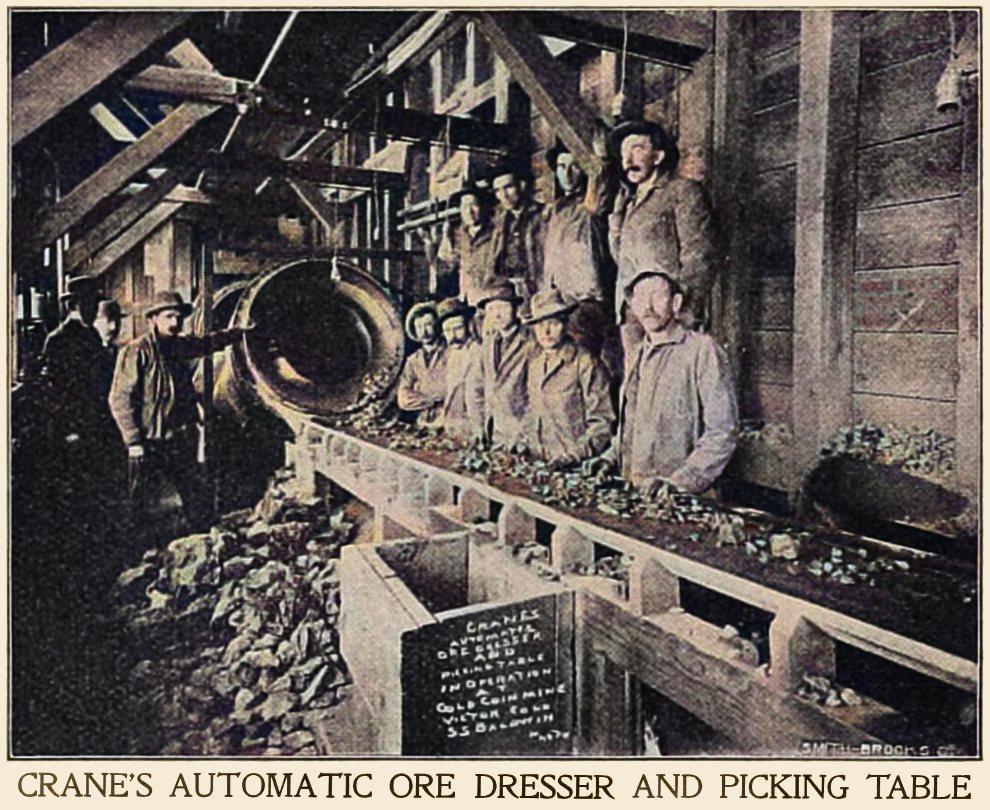

Cranes Automatic Ore Dresser and Picking Table in Operation at Gold Coin Mine Victor Colo.

Link to Source Image | Link used above is to Large 600dpi Scan from Seeing Cripple Creek

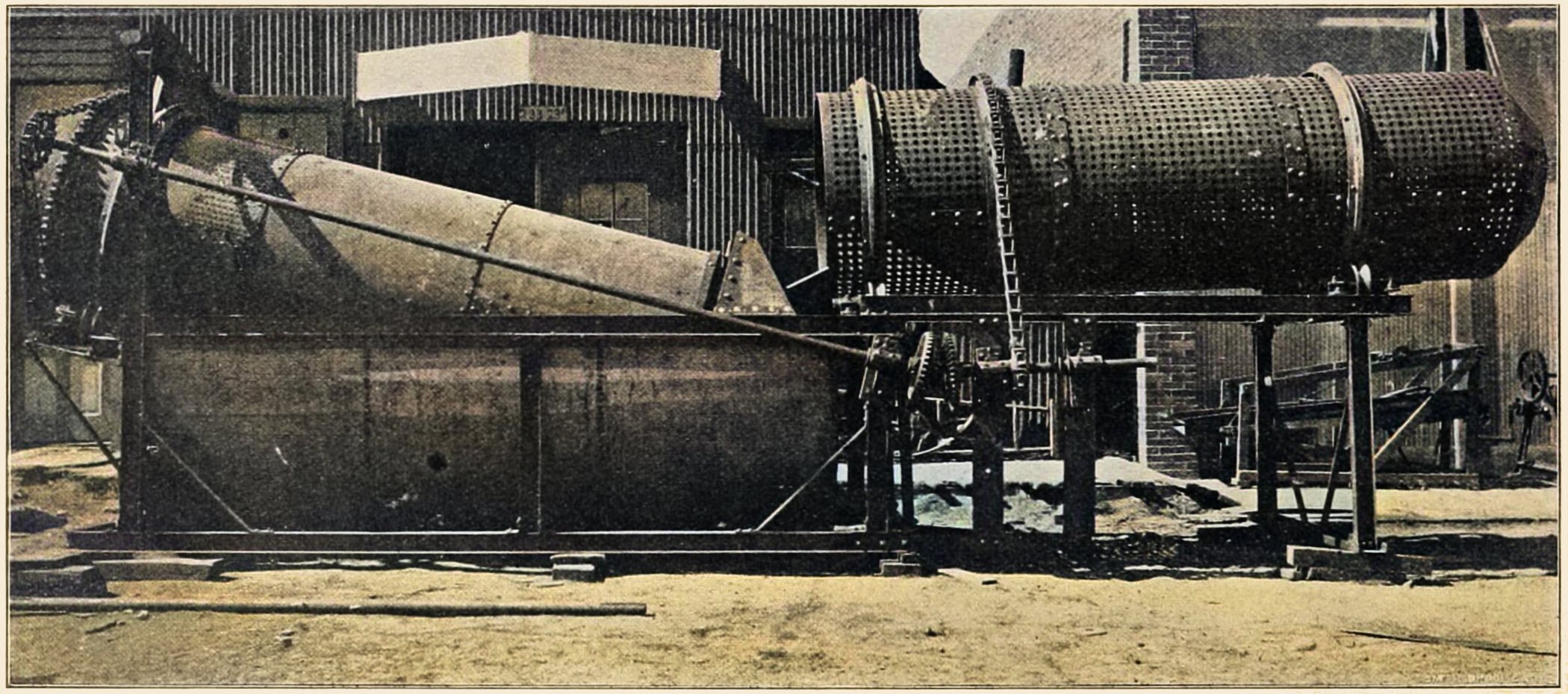

The ore direct from the mine is let into the screen by means of a chute, the screenings falling into a bin underneath the automatic rotary screen, from whence they are conveyed to any desirable locality. From the screen the ore falls into a large drum containing an Archimedean screw, which takes the rock through a water bath, thoroughly cleaning it.

Upon emerging from the drum the ore falls upon the picking belt, which takes the ore to any desired place. A great saving is effected thereby, for the reason that both hands of the ore sorter thus become free to use and very rapid work can be done.

The picking belt is, in reality, a traveling sorting table, and allows much freedom in the delivery of ore, as it can be taken anywhere to suit the topography of the country in which the mine may be located.

The Archimedean screw revolves at the rate of twelve revolutions to the minute, handling a minimum of 250 tons a day.

The traveling belt carrying the washed ore runs at the rate of eighteen feet per minute, just sufficient to take care of the output of the machine. The slimes and washings are caught in the tank, which is provided with a convenient man-hole for cleansing.

The economy of water used in the machine is one of the features to be recommended highly, especially where water is scarce. The water required to operate the machine will not exceed two barrels to the hundred tons of ore handled.

The power required to operate the machine is insignificant, two-horsepower being amply sufficient for all purposes. The machine being automatic in all parts, labor is unnecessary, save for the sorting, and here 100 per cent. is saved, as the men have both hands free for sorting purposes, and the ores being washed, sorting becomes a matter of merest simplicity.

The large leaks in most mines occur in the ore thrown over the dumps as waste, where high grade mineral is stacked up by the thousands of tons, which must be handled again in order to save the values. Where dump room is scarce, by reason of the fact that the picking tables can be lengthened and elevated so as to make an elevator of it, with the Automatic Ore Dresser and Picking Table clean dumps are assured.

The values heretofore lost by existing methods can now be saved by the Ore Dresser and the savings swell the dividends of the mine.

RECOMMENDATION.

Cripple Creek, Colo., Aug. 1, 1902.

To Whom it May Concern: We take pleasure in recommending the efficiency and economy of Crane's Automatic Ore Dresser. We have used this machine on the Doctor-Jack Pot mine for over a year, and its success has been so pronounced that we have ordered another machine for use on the Gold Coin mine.

We find that the greatest saving comes from leaving the dumps valueless. As a labor saver among the ore sorters, it recommends itself to anyone who has seen it in operation.

(Signed.)THE WOODS INVESTMENT CO.

![Photo by: William Henry Lehr [aka Bill Lehr] | Click for larger view, more info View in Abe Lincoln Ore House, Showing the Big Crane Washer and Picking Belt.](/04library/images/ofcial-suvnir15genral-asembly/p243_view-abe-lincoln-ore-house,showing-crane-washer-n-picking-belt_web-colored.jpg)