-> HathiTrust Digital Library Site; Link to Page.

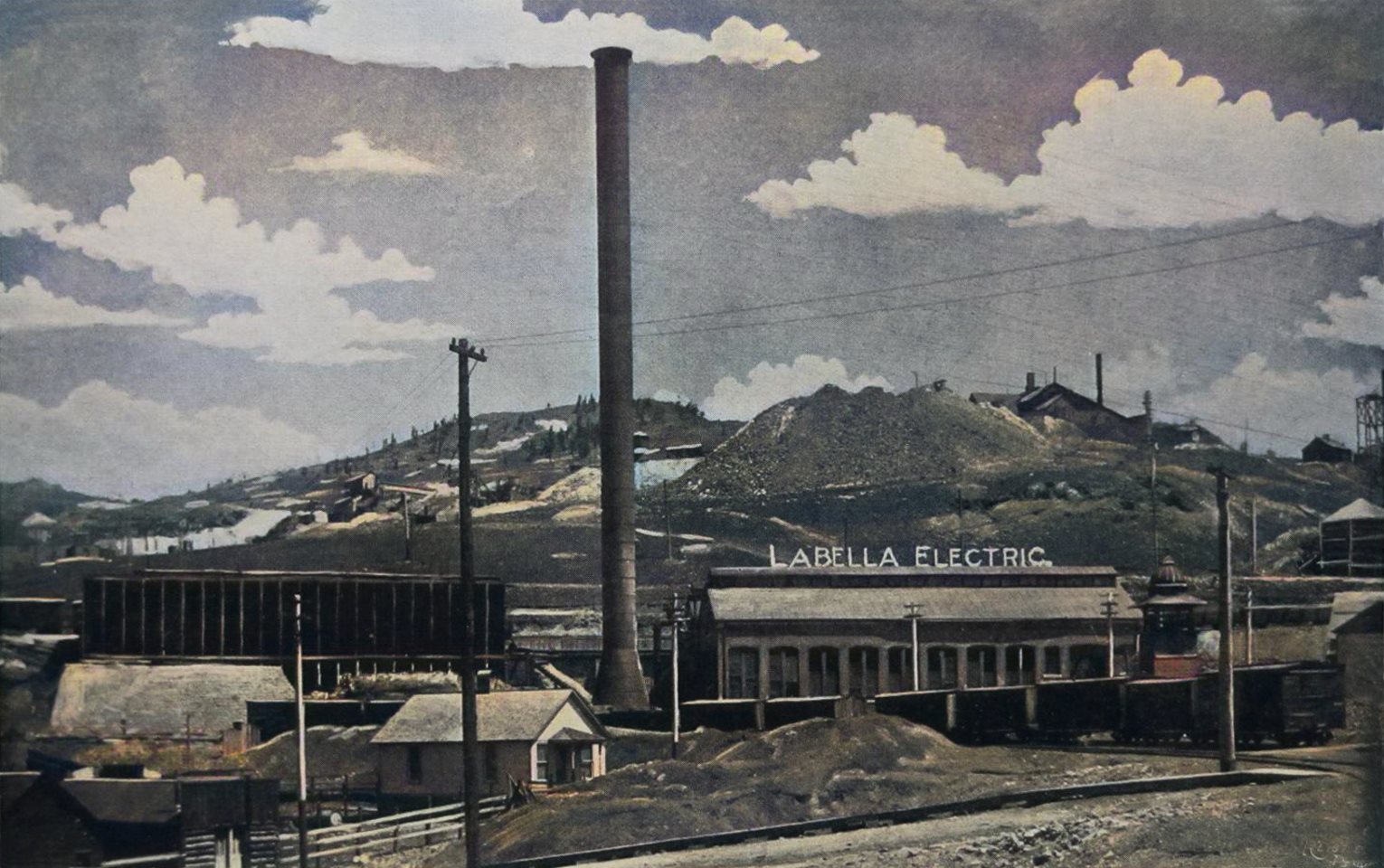

Source had no pics, only text, so I added from my collection, in addition to including a Sanborn Fire Insurance Map.

THE La Bella Mill, Water and Power company's plant at Goldfield is a notable addition to Cripple Creek as it is the first steel building erected in the district. The structure covers a space of about 10,000 square feet, and the roof ridge is 50 feet above the ground. Close to the building stands the steel stack, 210 feet high from the bottom of the flue, the steel portion alone standing 190 feet above the masonry.

The La Bella plant will operate the Florence and Cripple Creek and Golden Circle railroads and supply power, water and light to mines, mills and samplers.

The boiler equipment comprises six large boilers of the Babcock and Wilcox type, arranged in three batteries and capable of supplying the engines with steam for 3,000 horse power under normal conditions, with a maximum capacity of 4,500 horse power.

These boilers are mounted on elevated steel beams and a space is left underneath. Instead of carrying the smoke and gases to the stack over the boilers, in the usual way, they are carried downward into this basement space beneath the boilers and thus taken to the stack.

The space above the boilers is in this way left perfectly clear and nothing is visible in the boiler room to indicate the presence of a flue. The heat and the obstruction of the large flue is thus done away with in the boiler room.

The space above the boilers is entirely clear for the steam pipes and valves and these are readily accessible. A further use is made of the basement under the boilers in the handling of ashes. Instead of drawing the ashes from the fires into the boiler room, they are dropped into the basement to an ash conveyor and are carried directly to the cars on the track on the outside of the building.

The coal for the plant is likewise handled automatically, and without the usual dust and dirt in the boiler room. The coal is dumped from cars on an elevated track directly into the steel coal bins. These bins are inverted pyramids supported from the roof, the coal being dumped through the roof into the bins.

From the bins the coal falls into a weighing device, which in turn drops the coal to the automatic stokers. All the feeding of the coal is therefore accomplished by gravity. The stokers are of the Babcock and Wilcox type, having an endless chain grate.

After receiving the coal from the bins it is fed to the fires as the service may require it, and the ashes are carried on and dumped into the basement conveyor.

Next to the boiler room is the pump room, and in addition to the pumps for supplying the plant's requirements, provision has been made for furnishing water to the railroads, mines, mills and other consumers.

Underneath the pump room is a deep basement in which is located the economizer which saves the heat which would otherwise be carried away and wasted in the smoke stack.

Extending the full length of the building and adjoining both the boiler room and the pump room is the engine room, 110 feet long and 45 feet wide, and containing a large compressor and three large engines, driving electrical generators.

The combined engine capacity is 3,000 horse power. Over the entire engine room spans a powerful traveling crane capable of lifting any piece of machinery in the plant; by a novel design this crane is made to extend out of the building and overhang the railroad track and wagon road so that any piece of machinery is readily transferred to any portion of the engine room.

One of the conspicuous features of the engine room is the large compressor of the Ingersoll-Sargent type driven by an Allis Corliss engine. The compressing cylinders and the steam cylinders are both compound and the steam cylinders are condensing. The high pressure air cylinder has a diameter of 22 inches while the low pressure cylinder has a diameter of 40 inches, both having a stroke of 48 inches.

The capacity of the compressor being 5,000 feet of free air per minute, 50 drills could be operated, and even at the altitude of 10,000 feet above sea level, 35 drills can be operated.

Adjoining the compressor are the large engines coupled to the generators. The electric power will be used to operate the Florence and Cripple Creek railroad from Alta Vista to Cripple Creek and the Golden Circle railroad from Victor to Cripple Creek via Vista Grande. The surplus power will be used to operate the hoists, pumps, compressors, crushers, etc., in mines, mills, samplers, etc., throughout the district.

The engines are of the horizontal type and are compound condensing. The normal capacity of each engine is 750 horse power. The engines were built by the Mcintosh and Seymour company of Auburn, New York. The main shaft of the engine carries the electric generator, this shaft being 16 inches in diameter. The cylinders of these engines are 18 inches in diameter for the high pressure and 40 inches in diameter for the low pressure.

The generators were built by the General Electric company of Schenectady, New York, and generate a three-phase alternating current, of 3,600 alternations per minute. The pressure of 6,600 volts used on all outside wires, is reduced to 440 volts by means of a transformer.

The steam piping is so arranged that any pipe can be removed for repairs, or any part shut off for inspection, without disturbing the operation of the plant.

The engines are located within 10 feet of the boilers and the piping required is therefore very short, so the losses of heat are reduced to a minimum.

The exhaust piping is likewise very short, offering very slight resistance to the outlet from the engines to the condenser, which is of the elevated siphon type.

In the La Bella plant the water is used over and over again, and for the purpose of cooling there is erected a large tower, to extract the heat from the water; the water being then returned to the condenser to be used again.

This cooling tower is 110 feet long, 20 feet wide and 20 feet high, and is mounted on elevated ground near the building. Owing to its position, the top of the cooling tower is about 40 feet above the engine room floor. Water is pumped to the top of this tower and allowed to fall by gravity, and in this way it loses heat by contact with the air.

Mr. L. L. Summers was the consulting engineer, and the plans were prepared and the work executed under his personal direction.

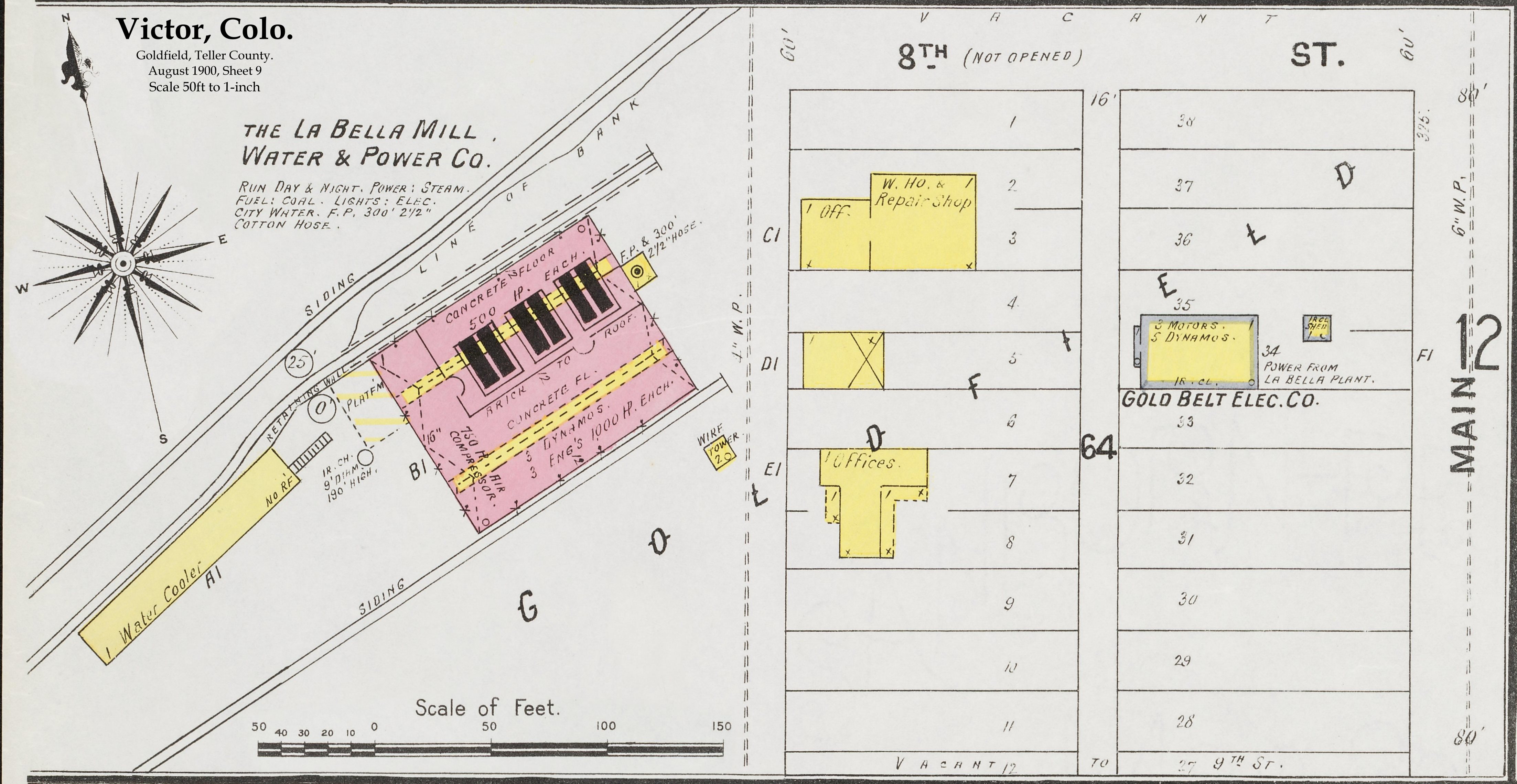

This is the 1900 Sanborn Fire Insurance Map for the La Bella Mill, Water & Power Company. The power plant part is on the left side, while some of the street pattern in the town of Goldfield and associated buildings are on the right side, including Offices and Warehouse & Repair Shop.

This is the 1900 Sanborn Fire Insurance Map for the La Bella Mill, Water & Power Company. The power plant part is on the left side, while some of the street pattern in the town of Goldfield and associated buildings are on the right side, including Offices and Warehouse & Repair Shop.

I reposition and added in some info-pieces from other places on the larger sheets this is cropped out of, also, I straightened it along street lines, but other than that, the map is as it was made. The Key is not included as there were no room, but simplified; Yellow = Frame (Wood) Structures; Red = Brick Structure; Numbers in Circle = Relative Heights.

I reposition and added in some info-pieces from other places on the larger sheets this is cropped out of, also, I straightened it along street lines, but other than that, the map is as it was made. The Key is not included as there were no room, but simplified; Yellow = Frame (Wood) Structures; Red = Brick Structure; Numbers in Circle = Relative Heights.